In my early years on site, I believed high hardness meant long life. Many suppliers said the same thing. But reality in the mill was very different. I saw high-chromium rollers crack, spall, and fail far earlier than expected, even when hardness numbers looked perfect. Every failure meant lost production, rushed repairs, and long meetings asking the same question again and again.

High-chromium rollers often fail early because their microstructure is brittle, their toughness margin is low, and real mill conditions combine impact, heat change, and high contact stress. These factors create cracks that grow quickly and cause spalling, vibration, and sudden shutdowns.

Over time, I learned to stop blaming only “bad operation.” Instead, I started to look at how material behavior, casting quality, heat treatment, and real load conditions interact. Once you see that whole picture, early failure is no longer a mystery. It is often predictable.

What causes my high-chromium roller sleeves to crack during heavy impact?

Cracking under impact is one of the most common failure modes I have seen. High-chromium alloys contain large volumes of hard carbides. These carbides give wear resistance, but they also reduce toughness. During casting, carbides can segregate. This creates local brittle zones. Under impact, stress does not spread evenly. It concentrates at those weak zones, and cracks begin.

Another factor is residual stress. If cooling is uneven or machining is aggressive, stress remains locked inside the sleeve. When the mill starts, operating stress adds on top of that residual stress. The material reaches its limit faster than expected. Cracks often start below the surface, where contact stress is highest, and then grow outward.

From my experience, impact damage is rarely a single event problem. It is a fatigue problem driven by repeated shocks. Each shock grows the crack a little more until one day it becomes visible or catastrophic.

| Observation in the mill | Root cause inside the material | Result over time |

|---|---|---|

| Cracks appear soon after start-up | High residual stress | Rapid crack growth |

| Cracks start below surface | High contact stress | Sudden surface failure |

| Repeated cracks in same zone | Carbide segregation | Short service life |

Why does my roller surface spall when grinding hard clinker or slag?

Spalling is often misunderstood as simple wear. In reality, it is usually a fracture process. When grinding hard clinker or slag, the roller surface experiences very high compressive and shear stress. In high-chromium material, the matrix between carbides has limited ability to deform. Microcracks form below the surface where shear stress peaks.

Thermal effects add another layer of damage. When material flow is unstable, surface temperature changes quickly. This causes thermal fatigue. Small surface cracks form and link up with subsurface cracks. Eventually, a piece of material breaks away. Operators see sudden spalling, but the damage has been growing quietly for weeks.

I have seen spalling accelerate when water spray control is poor or when feed chemistry changes. These factors do not destroy the roller instantly, but they push a brittle structure closer to its limit.

| Spalling feature | Driving force | Why it accelerates |

|---|---|---|

| Fine pits | Cyclic stress | Cracks link together |

| Large flakes | Subsurface cracks | Low fracture resistance |

| Spalling after heat swings | Thermal fatigue | Expansion mismatch |

How can I reduce the rapid wear I’m seeing on my current high-chromium rollers?

Rapid wear is rarely only abrasion. In harsh mills, wear often includes micro-chipping, chemical attack, and fatigue. Corrosive dust or sulfur compounds can damage the chromium-rich oxide layer. Once that layer is broken, abrasion removes fresh metal faster. Poor lubrication increases friction heat, which weakens the surface even more.

Process stability matters as much as material. When the bed is unstable, the roller impacts the table directly. What looks like wear is often impact-driven chipping. This is why two plants using the same roller material can see very different life.

In practice, I reduce rapid wear by combining process control with better material matching. Simply increasing hardness usually makes the problem worse.

| Action I take | Effect in operation | Long-term benefit |

|---|---|---|

| Improve bed stability | Less impact | Slower damage growth |

| Control lubrication | Lower heat | More stable surface |

| Review feed chemistry | Less corrosion | Lower chemical wear |

| Upgrade material design | Better toughness | Predictable wear |

Is the toughness of my high-chromium rollers too low for my mill conditions?

Many mills unknowingly operate beyond the toughness limit of high-chromium rollers. These alloys perform well under steady abrasion, but they struggle under shock and vibration. If your mill experiences frequent load changes, tramp metal, or large feed size variation, toughness becomes more important than hardness.

I have seen cases where increasing hardness reduced service life by half. The roller resisted abrasion but cracked early. This happens because cracks grow faster in brittle materials. Once toughness is too low, no amount of hardness can save the sleeve.

When cracks dominate failure, the answer is usually not better operation alone. It is a material mismatch.

| Failure symptom | What it tells me | Needed improvement |

|---|---|---|

| Sudden breakage | Toughness too low | Higher crack resistance |

| Edge chipping | Stress concentration | Tougher edge design |

| Repeated spalling | Fatigue cracking | Better fatigue behavior |

How does uneven wear on my rollers lead to vibration and shutdowns?

Uneven wear changes how load is carried. When one area wears faster, the roller no longer contacts the bed evenly. This causes vibration. Vibration increases dynamic load, which increases crack growth rate. The system enters a negative loop.

I have watched mills run “normally” while vibration slowly increased. By the time alarms triggered, internal cracks were already large. This is why uneven wear should be treated as an early warning, not a cosmetic issue.

| Uneven wear sign | System reaction | Final risk |

|---|---|---|

| Local flat spots | Load shift | Bearing damage |

| Wavy surface | Bed instability | Sudden spalling |

| Edge over-wear | Stress rise | Edge cracking |

Can metal-ceramic composite roller sleeves solve my premature failure problem?

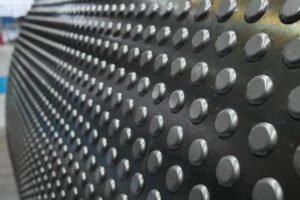

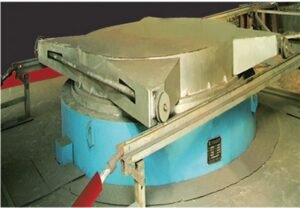

In harsh conditions, I prefer materials that balance wear resistance and toughness. Metal-ceramic composite rollers aim to do this. They use ceramic reinforcement for abrasion resistance and a tough metal matrix to stop cracks from spreading.

The biggest advantage I see is stability. When ceramics are well bonded and supported, there is no ceramic falling and no stud drop. The surface stays consistent, which keeps vibration low. Crack growth slows because the base material can absorb energy.

This approach fits mills that cannot avoid shock and high load.

| Design concept | Main advantage | Failure risk reduced |

|---|---|---|

| Pure high-chromium | Simple and hard | Crack-driven failure |

| Composite structure | Balanced behavior | Early spalling |

| Graded toughness | Stress control | Sudden breakage |

This is the direction we take at Dafang-Casting, based on many real failure cases.

Why do my refurbished or welded rollers fail faster than expected?

Refurbishment introduces heat, and heat changes structure. If welding heat is too high, a brittle heat-affected zone forms. This zone cracks easily. Residual stress is another issue. Without proper stress relief, welded rollers start service already close to their stress limit.

Bond quality also matters. If the rebuilt layer does not bond perfectly, cracks grow along the interface. Under cyclic load, this becomes delamination.

| Rebuild risk | Why it occurs | Typical result |

|---|---|---|

| Brittle HAZ | Excess heat | Surface cracking |

| Residual stress | Poor control | Early failure |

| Weak bonding | Interface defects | Layer peeling |

How can I extend the service life of my rollers in high-load VRM operations?

In high-load VRM service, I focus on reducing crack growth. This means choosing tougher materials, ensuring uniform heat treatment, and stabilizing operation. Uniform structure gives uniform wear. Stable operation reduces shock. Together, they slow damage accumulation.

In many cases, switching to a composite or tougher alloy gives the biggest gain. Not because wear rate drops dramatically, but because failure becomes predictable.

| Focus area | Why it matters | Result |

|---|---|---|

| Material toughness | Slows cracks | Longer safe life |

| Heat treatment quality | Uniform behavior | Even wear |

| Bed stability | Lower impact | Less spalling |

| Lubrication | Lower heat | Surface protection |

What material should I choose if my plant handles abrasive or high-impact materials?

Material choice should start with failure mode, not hardness. For abrasive but stable conditions, high-chromium can work. For abrasive and high-impact conditions, a tougher solution is safer. Composite designs or alternative alloys handle mixed loads better.

I always ask: will this material fail by slow wear or sudden cracking? Slow wear is easier to manage and cheaper in the long run.

| Condition | Priority | Recommended direction |

|---|---|---|

| High abrasion | Wear resistance | Quality high-chromium |

| High abrasion + impact | Toughness | Composite rollers |

| Corrosion present | Chemical stability | Composite + control |

| Thermal cycling | Fatigue resistance | Stable structure |

How do I verify which roller sleeve will give me the lowest cost per operating hour?

I verify with real operating data. Purchase price is only one part. I calculate total cost, including downtime, changeout labor, and collateral damage. Then I divide by operating hours. I also look at failure mode. Predictable wear is safer and cheaper than sudden cracks.

| Metric | Why I track it | Insight gained |

|---|---|---|

| Operating hours | True life | Wear behavior |

| Shutdown time | Hidden cost | Stability impact |

| Vibration trend | Early warning | Risk level |

| Failure photos | Root cause | Material match |

| Total cost | Final metric | Best choice |

Conclusion

High-chromium rollers fail early when brittle structure, low toughness, thermal fatigue, and high contact stress work together. In harsh VRM conditions, hardness alone is not enough. I focus on crack resistance, structural uniformity, and stable operation. For many plants, Dafang-Casting metal-ceramic composite roller sleeves offer a safer path to longer life, fewer shutdowns, and a lower cost per operating hour.