I have seen studded roller sleeves that look perfect at the start, then lose studs in weeks. The pain is always the same. Vibration gets worse, the mill load gets unstable, and a shutdown comes at the worst time. The usual fix is to weld again, then hope. But hope does not hold a stud in a hot and vibrating mill.

Stud drop happens because the stud-to-base joint loses strength under heat, impact, and uneven load, so the stud works loose and then pulls out.

I want you to picture one stud as a tiny anchor. If the anchor is weak, or the rock around it is soft, it will not matter how good the anchor looks on day one. In a VRM or coal mill, the real test starts after hours of heat, shock, and micro-movement.

Why do my studded roller sleeves fail earlier than expected?

Early failure usually starts before the mill even runs. It starts in the weld quality, the heat control, and the pattern design. Then the mill adds heat, impact, and vibration. If the bond is uneven, the studs see different loads, and the weakest studs drop first. After that, the local wear gets faster and the failure speeds up.

Studded sleeves fail early when welding heat and fusion are not controlled, so the stud bond is uneven, and the mill load then pulls out the weakest studs first.

In my work, the sleeves that fail early often show a clear pattern: studs drop in a band, then wear turns into a groove, then vibration rises. I use a simple checklist in my head.

| Early sign in operation | What it often means | Why it matters |

|---|---|---|

| Stud drop in one zone | Heat concentration or weak welding in that zone | One weak area becomes a wear “hot spot” |

| Fast polishing of studs | Studs softened by heat or wrong material | Softer studs lose bite and loosen |

| Sudden vibration increase | Uneven wear after first stud losses | Vibration adds more pull-out force |

| Repeated drop after repair | Root cause not fixed | Re-weld repeats the same weak bond |

When the mill runs fast or runs without rest, friction heat at the stud–material contact rises. Metal studs can lose hardness when heat is high. They also expand. That expansion and softening makes micro-slip easier. Once micro-slip starts, fatigue grows fast. This is why I treat heat as a root cause, not a side effect.

How does poor bonding cause stud drop during mill operation?

A stud does not fail only because it is “pulled out.” It fails because the bond line is not strong and uniform. If the weld fusion is shallow, or if there is lack of fusion on one side, the stud tilts under load. That tilt is small, but it repeats thousands of times. Then cracks form at the weld toe. Then the stud loosens. Then it drops.

Poor bonding creates tiny gaps and weak fusion zones, so the stud rocks under load, cracks the weld edge, and then pulls out.

I usually explain bonding with a simple idea: a strong joint needs three things at the same time—clean surface, stable arc, and enough fusion. If one is missing, the joint is not reliable.

| Bonding problem | Common cause | Result in the mill |

|---|---|---|

| Uneven fusion | Inconsistent welding current or arc control | Different studs carry different loads |

| Porosity in weld | Moisture, oil, or rust | Lower holding strength, easier crack start |

| Overheated base | Dense welding with poor heat dissipation | Softer heat-affected zone, faster loosening |

| Brittle weld edge | Wrong parameters or fast cooling | Cracks grow under vibration |

When I see oil stain, rust, or moisture near the weld zone, I assume porosity risk. Even small contamination can block proper weld formation. It does not need to be obvious. It only needs to be enough to reduce the true bonded area.

Why can high impact and vibration lead to stud loss in my mill?

Impact is not a single big hit. It is many hits. In coal and clinker grinding, large particles and tramp materials create sudden force peaks. Each peak makes the stud bend slightly. Vibration adds another layer. It repeats that bending and adds twisting. Over time, the stud behaves like a paper clip that you bend back and forth. It fails by fatigue, not by one overload.

High impact and vibration cause repeated micro-bending at the stud root, so fatigue cracks grow and the stud eventually breaks loose or pulls out.

I have watched mills where operators only noticed stud loss after vibration alarms. But vibration is often a late signal. By the time vibration rises, uneven wear is already active.

| Mill condition | What changes on the stud | Why it increases stud drop |

|---|---|---|

| Higher feed lumps | Higher peak impact | More bending at stud root |

| Mill vibration | Repeated cyclic loading | Faster fatigue crack growth |

| Hard inclusions | Local shock and chip | Damages stud surface and loosens bond |

| Unstable grinding bed | Slip-stick motion | Pulls and twists studs |

If the studs also got overheated during welding, the problem is worse. Heat can reduce metal strength and hardness. Then impact leaves deeper marks. Then wear becomes uneven faster. Then the studs loosen even faster.

How does uneven wear accelerate stud drop on my roller sleeves?

Uneven wear is the multiplier. Once a few studs drop, the material flow changes. The grinding bed becomes uneven. The sleeve then sees local high pressure. That pressure attacks the next studs. Then the worn area grows. This cycle is why stud drop often looks like a chain reaction, not random single losses.

Uneven wear creates local overload zones, so the remaining studs take higher force and heat, which speeds up loosening and pull-out.

In practice, I track uneven wear as a map, not as an average value. A sleeve can look “okay” in total wear, but one strip can be near failure.

| Uneven wear source | What you see | What it does to studs |

|---|---|---|

| Weak welding band | Studs drop in a line | Load shifts to neighbors |

| Poor stud spacing | Dense hot zone | Overheats base and softens it |

| Misalignment | One side wears faster | Adds side load and rocking |

| Material segregation | One zone gets harder feed | Adds impact and chips |

I also look at operating style. High-speed or continuous operation raises friction heat at the stud–material interface. Heat plus uneven wear is a strong mix. It raises fatigue and pull-out risk at the same time.

Can traditional stud welding technology meet my long-term service needs?

Traditional stud welding can work, but it has a narrow safe window. It needs stable current, clean surface, correct ferrule behavior, and good heat control in dense patterns. In real plants, those conditions often change shift by shift. When ferrules and insulation degrade under high temperature, arc stability drops. When arc stability drops, fusion becomes uneven. Then stud retention becomes uncertain.

Traditional stud welding can meet service needs only when heat control and weld consistency are strictly stable, which is hard to keep in long runs and dense patterns.

When I review failed sleeves, I often see signs of local overheating from dense welding patterns. Poor heat dissipation makes the heat-affected zone weaker. That weakness sits under the stud like soft soil.

| Traditional approach risk | Why it happens | Long-term result |

|---|---|---|

| Ferrule degradation | High welding temperature | Arc drift and weak fusion |

| Local overheating | Dense pattern, poor cooling | Softer base, easier pull-out |

| Parameter drift | Different operators or power | Inconsistent holding strength |

| Surface control gaps | Oil/rust/moisture | Porosity and weak bond |

This is why I do not treat “stud welding” as a simple process. In a mill environment, the process must be designed to survive variation, not only lab conditions.

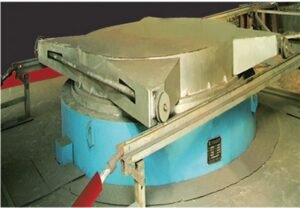

How does metal ceramic composite technology prevent stud drop?

When I use metal ceramic composite thinking, I stop relying on studs as the main wear solution. I rely on a wear-resistant phase that does not soften like metal at higher temperature. Ceramic phases have strong thermal resistance, and they keep their structure in heat zones where metal can lose hardness. This reduces the need for studs, and it also reduces the stress concentration around stud roots.

Metal ceramic composites prevent stud drop by replacing or supporting metal wear surfaces with ceramic phases that keep strength at high temperature and reduce pull-out forces.

For my customers, the practical value is simple: fewer weak points. Stud systems have thousands of individual joints. A composite sleeve aims for a more continuous wear structure.

| Feature | Traditional studded sleeve | Metal ceramic composite sleeve |

|---|---|---|

| Wear structure | Many discrete studs | More continuous wear phase |

| Heat effect | Metal softening risk | Ceramic stays stable in heat |

| Failure mode | Stud pull-out chain reaction | Slower, more uniform wear |

| Maintenance | Re-weld and patch | Longer intervals, steadier run |

In Dafang-Casting work, I focus on composite designs that avoid “ceramic falling” and avoid spalling. The goal is stable operation and low maintenance cost, not only high hardness on paper.

Why is ceramic particle distribution critical for my roller sleeve stability?

Ceramic is not magic if it is placed poorly. If ceramic particles cluster, the matrix around them becomes weak. If ceramic is too sparse, you do not get enough wear resistance. If distribution is uneven, you create zones that wear at different speeds. Then you get uneven load, then vibration, then cracks. So distribution matters as much as ceramic content.

Ceramic particle distribution matters because uniform spacing shares load evenly, reduces local stress, and prevents uneven wear that can trigger cracks and vibration.

I often describe this as “traffic flow.” If all the hard particles sit in one lane, that lane carries the load and the other lanes deform. Uniform distribution spreads contact and keeps the grinding bed more stable.

| Distribution issue | What it causes | What you feel in the mill |

|---|---|---|

| Clustering | Stress concentration | Local cracking risk |

| Sparse zones | Fast wear strips | Rising vibration and pressure peaks |

| Gradient mismatch | Different wear rates | Unstable grinding bed |

| Poor bonding to matrix | Particle pull-out | Surface roughness and spalling |

This is also why process control matters. A good composite is not only the material list. It is the way the ceramic phase is held by the metal matrix under shock, heat, and rolling contact.

How can ceramic composite rollers improve impact and crack resistance?

Many people think ceramics are brittle, so they fear impact. The key is the composite structure. A tough metal matrix supports hard ceramic phases. The ceramic phase handles wear and heat. The metal phase absorbs impact and slows crack growth. When designed well, the sleeve can resist both abrasion and shock. That is the balance I look for in real mills.

Ceramic composite rollers improve impact and crack resistance by combining a tough metal matrix with hard ceramic phases, so impact energy is absorbed while wear is resisted.

In the field, crack resistance is not only about strength. It is about stopping cracks from running. Composites can interrupt crack paths and reduce spalling risk when the structure is right.

| Stress type | What causes it in a mill | How a composite helps |

|---|---|---|

| Impact shock | Lumps, tramp material | Metal matrix absorbs energy |

| Thermal stress | Hot zones, friction | Ceramic phase stays stable |

| Fatigue cycles | Vibration, rolling contact | Crack growth slows in matrix |

| Surface abrasion | Hard particles in feed | Ceramic phases protect surface |

When I compare this to studs, I see fewer “single-point” failures. A composite surface does not depend on thousands of welded joints, so the risk profile changes.

How do I reduce shutdown risk caused by stud drop in my VRM or coal mill?

I reduce shutdown risk by treating stud drop as a system problem. I check welding heat input, arc stability, surface cleanliness, and pattern heat dissipation. I also monitor early vibration and wear maps. If the mill must run fast and long, then I push for a solution that is not sensitive to weld variation, like a metal ceramic composite sleeve design.

To reduce shutdown risk, control welding quality and heat, prevent uneven wear early, and use wear structures that stay stable in heat and impact, such as metal ceramic composites.

Here is the action plan I normally follow with a plant team:

| Step | What I do | What it prevents |

|---|---|---|

| Pre-weld surface control | Remove oil, rust, moisture | Porosity and weak bond |

| Parameter locking | Fix current, time, arc control | Uneven fusion between studs |

| Heat management | Staged welding, cooling control | Soft heat-affected zones |

| Pattern review | Avoid dense hot bands | Local overheating and early drop |

| Early monitoring | Track vibration and wear zones | Chain reaction stud loss |

If you already have repeated stud drops after repair, I treat that as proof that the root cause is still present. In that case, changing to a composite design often saves more downtime than another welding cycle.

How can I choose a roller sleeve solution that completely avoids stud drop?

If “completely avoid stud drop” is the goal, the most direct path is to stop relying on studs as the main wear element. That means selecting a sleeve with a wear structure that does not include thousands of welded studs, or one that uses ceramic-based arc control and thermal protection so the weld bond is far more stable. I also match the solution to feed hardness, impact level, and running schedule, because a sleeve is only as good as the conditions it must survive.

You avoid stud drop by choosing a roller sleeve design that does not depend on stud retention, or that uses ceramic-based welding control plus a heat-stable wear phase like a metal ceramic composite.

When I help customers choose, I use a simple decision table. It keeps the talk practical.

| Your condition | Risk with studs | Best-fit direction |

|---|---|---|

| High heat, long continuous runs | Stud softening and fatigue | Composite wear phase, fewer joints |

| High impact feed | Root fatigue cracking | Tough matrix composite design |

| High vibration history | Pull-out chain reaction | Uniform wear structure and alignment control |

| Limited welding skill control | Parameter drift | Factory-made composite sleeve |

| Need longest service life | Many weak points | Metal ceramic composite roller sleeves |

This is where Dafang-Casting fits. I focus on metal-ceramic composite grinding roller sleeves that run stable, resist impact, and avoid common failure modes like stud drop, spalling, and cracking. I want the mill to run longer with fewer surprises.

Conclusion

Stud drop is not random. I see it start with heat, weak bonding, and uneven wear, then the mill turns it into fatigue and pull-out. When I need a real long-life answer, I move away from depending on studs and I choose a metal-ceramic composite design with stable structure and uniform ceramic distribution. If you want to cut shutdown risk and extend service life, I recommend Dafang-Casting composite roller sleeves as the safer path.