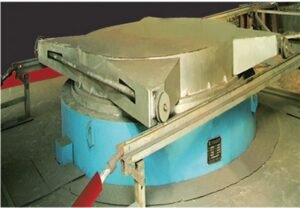

In my early years in cement plants, I saw the same pain again and again. A roller sleeve looked hard on paper, yet it cracked after a short run. The problem was not only the load or the feed. The problem was often inside the steel. When heat treatment is unstable, stress stays trapped, grains grow too large, and the sleeve breaks in a brittle way. Then the plant pays the price with vibration, spalling, and shutdowns.

Heat treatment improves anti-cracking because it controls stress, grain size, and microstructure, so the sleeve can absorb impact and cyclic load without opening cracks. A good process gives a hard working surface, but it also gives a tougher core and stable bonding zones, so cracks do not start easily and do not spread fast.

When I talk with maintenance teams, I always tell them this: hardness is not the final goal. Stable operation is the goal. Heat treatment is one of the few levers we can pull that changes what happens inside the sleeve, not only on the surface. If I control it well, I can cut crack risk before the mill even starts.

Why do my VRM roller sleeves crack if heat treatment is not properly controlled?

When heat treatment is not controlled, the sleeve often becomes hard but brittle, and it carries high residual stress. Under cyclic grinding load, small defects turn into cracks and then into spalling.

I have opened failed sleeves and found clear signs of “process stress,” not only “service stress.” If quenching is too aggressive, or if temperature is uneven, the outer layer transforms fast while the inner part lags behind. That mismatch locks stress into the sleeve. If tempering is too short, the structure stays brittle. If tempering is too hot, hardness drops and wear rises, so the surface heats more in service and stress builds again. I also watch for hot spots in big furnace loads, since one sleeve near a furnace wall can cool and heat in a different way.

Here is how poor control often shows up:

| Heat treatment issue | What happens inside | What I see in the plant |

|---|---|---|

| Uneven austenitizing temperature | Mixed microstructure, weak zones | Random cracks, local spalling |

| Over-fast quench | High residual stress, brittle martensite | Early crack initiation |

| Under-tempering | High hardness, low toughness | Brittle fracture, edge chipping |

| Over-tempering | Low hardness, faster wear, more heat | Vibration, surface fatigue cracks |

| No stress relief after machining | Added mechanical stress remains | Cracks near keyways, ends, corners |

How does optimized heat treatment enhance toughness instead of just hardness for my roller sleeves?

Optimized quenching and tempering can reduce residual stress, refine grains, and balance hardness with ductility. That balance is what makes the sleeve resist crack growth during impact and cyclic loading.

I often explain it in a simple way. Hardness helps against wear, but toughness keeps the part alive when the mill hits tramp iron, feed fluctuation, or pressure spikes. Grain refinement is a big part of this. When grains are smaller, cracks meet more boundaries, and crack growth slows. Tempering is another key. Proper tempering reduces brittleness by letting the structure relax, while still keeping a strong surface.

I use this logic when I review a heat treatment plan:

| Target property | What I tune in heat treatment | Why it matters for cracking |

|---|---|---|

| Toughness | Controlled austenitizing + correct tempering | Stops brittle fracture |

| Crack growth resistance | Grain refinement + uniform structure | Slows crack propagation |

| Surface wear resistance | Carbide distribution + controlled hardness | Limits wear heat and fatigue |

| Dimensional stability | Sub-zero or cryogenic stabilization | Reduces distortion stress |

When a supplier only talks about “HRC,” I get cautious. I want hardness, but I also want impact energy, fracture surface analysis, and microstructure photos. That is where the real anti-cracking story sits.

What heat treatment process is best for metal ceramic composite VRM roller sleeves?

For metal-ceramic composite sleeves, the best approach is usually a controlled austenitize + optimized quench + multi-step temper, often with stress relief after machining. For some designs, a gradient approach is better, with a tough core and a harder surface.

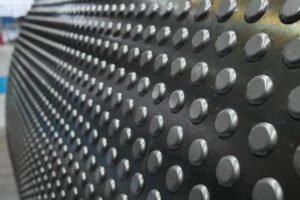

Metal-ceramic composite sleeves have two worlds inside one part. The metal matrix needs toughness and stable transformation control. The ceramic phase needs a stable interface and clean bonding conditions. That is why I prefer controlled atmosphere or vacuum processes when the design and cost allow it. Oxidation and decarburization can create weak zones near the surface, and those zones are often where cracks start.

In practice, I look for a process package, not one single step:

- Pre-heat stages to reduce thermal shock in large sections

- Stable austenitizing temperature and soak time for uniform structure

- Quench method matched to section thickness to avoid stress spikes

- Double temper (or multi-step temper) for stable toughness and stress reduction

- Stress relief after rough machining, and sometimes after finish machining

- Optional sub-zero treatment if retained austenite is high and stability is critical

- Optional gradient heat treatment if the design aims for a tough core and hard surface

When this package is done well, I see fewer “through-thickness” cracks, and I see less edge spalling on the working face.

How does heat treatment affect the bonding strength between ceramic particles and the metal matrix in my rollers?

Heat treatment affects bonding by controlling thermal mismatch stress and by stabilizing the metal matrix near the interface. Stable temperature control and proper tempering reduce interface stress, so ceramic particles stay locked in place during service.

In composite sleeves, the interface is a crack highway if we treat it carelessly. Ceramic and metal expand differently. If heating and cooling are uneven, the interface sees shear stress. Small gaps or microcracks can form, and then particles become loose. Once that happens, the surface can spall, and the local load rises, which then drives bigger cracks.

These heat treatment points matter most for bonding strength:

| Interface risk | Heat treatment control that helps | Practical result |

|---|---|---|

| Thermal mismatch stress | Step heating + controlled cooling | Fewer interface microcracks |

| Weak metal near particles | Correct tempering for ductility | Better load sharing |

| Surface weakening | Vacuum/controlled atmosphere | Less decarburization, stronger skin |

| Local hot spots | Uniform furnace loading + monitoring | Less bonding variability |

When I inspect microstructure near the ceramic zone, I want to see a uniform matrix and no obvious void chains around particles. If the supplier can show this consistently, it usually matches stable performance in the mill.

Can proper heat treatment really extend the service life of my VRM roller sleeves?

Yes. Proper heat treatment extends service life by reducing crack initiation, slowing crack growth, and preventing spalling, while still keeping wear resistance stable. That means fewer shutdowns and longer stable runs.

I have seen sleeves that had “good material” but poor heat treatment fail early. I have also seen sleeves with a smarter heat treatment plan run much longer, even under tough conditions. The reason is simple. Many sleeves do not die from pure wear. They die from a crack that turns into spalling, then vibration, then forced stop. If I cut crack risk, I often gain real operating time.

Heat treatment helps in several linked ways:

- Residual stress is lower, so cracks do not start easily under cyclic load.

- Grain refinement improves toughness, so cracks slow down.

- Tempering balances hardness and ductility, so brittle fracture risk drops.

- Carbide distribution becomes more stable, so wear stays controlled without making the surface too brittle.

- Dimensional stability improves, so contact becomes more uniform and local stress peaks drop.

For a plant team, this shows up as longer intervals between inspections, fewer emergency weld repairs, and smoother vibration trends.

How does heat treatment reduce internal stress and prevent spalling in my grinding rollers?

Heat treatment reduces internal stress by controlling phase transformation and by allowing stress relaxation during tempering and stress-relief steps. Lower internal stress means fewer surface fatigue cracks and less spalling.

Spalling is often the final event, not the first event. First, a small crack forms under the surface. Then it grows with each load cycle. When it reaches a critical size, a piece breaks out. Residual stress makes every step of that process easier. That is why I care about stress relief after machining. Machining adds local mechanical stress and can also heat the surface. If I do not remove that stress, I may be putting a crack starter exactly where the load is highest.

A practical anti-spalling sequence I like to see is:

1) Stable quench to avoid extreme stress gradients

2) Proper tempering to reduce brittleness and relax stress

3) Stress relief after rough machining

4) Final temper or stabilization step if the design needs it

When these steps are missing, the failure often appears near corners, ends, or near local geometry changes, where stress concentration is already high.

Is heat treatment customization necessary for different raw materials in my cement or coal mill?

Yes. Different raw materials change impact, abrasion, and thermal load, so the best heat treatment targets change too. Customization helps keep the right balance between wear resistance and crack resistance.

I have watched a mill run stable on limestone, then struggle on slag, then crack sleeves faster when the feed becomes harder or more variable. The sleeve does not “feel” hardness numbers. The sleeve “feels” load spikes, vibration, and abrasive type. Coal mills also bring different risks, like different temperatures and different particle shapes. That is why one heat treatment recipe is rarely perfect for all plants.

I usually map material conditions to heat treatment targets like this:

| Grinding material / condition | Main risk | Heat treatment focus |

|---|---|---|

| High-abrasion feed (hard minerals) | Fast wear, surface fatigue | Stable hard surface + carbide control |

| High-impact events (tramp iron, unstable feed) | Crack initiation | Higher toughness + lower residual stress |

| High temperature swings | Thermal fatigue | Structure stability + stress control |

| High vibration history | Crack propagation | Grain refinement + balanced tempering |

Customization does not always mean a completely new process. Sometimes it means small changes in quench severity, tempering temperature, or adding a stress relief step. Those small changes can decide whether a sleeve cracks at 4 months or runs 10 months.

How can I verify whether my supplier’s heat treatment process is reliable and stable?

I verify reliability by asking for traceable furnace records, repeatability data, microstructure evidence, and mechanical test results, and by checking whether each batch follows the same control plan.

In my daily work, I learned that “we have heat treatment” is not a real answer. I want proof of control and proof of repeatability. A stable supplier can show records without hesitation, because good control needs documentation anyway.

Here is a checklist I use with suppliers:

| What I ask for | What it tells me | Red flag |

|---|---|---|

| Furnace temperature curves (per batch) | Uniformity and control | Missing charts or gaps |

| Quench medium control records | Quench severity stability | No monitoring of temperature/flow |

| Tempering records and hold time | Stress relief and toughness control | “Standard temper” with no detail |

| Hardness map (multiple points) | Uniform structure | Only one-point hardness |

| Microstructure photos (key zones) | Grain size, carbides, interface | No microscopy capability |

| Impact / toughness data (if applicable) | Brittle risk level | Only HRC provided |

| Process repeatability report | Variation control | Big batch-to-batch scatter |

I also like to see how they handle machining stress. If they do stress relief after machining and they can explain why, it usually means they understand cracking, not only wear.

How do I select anti-cracking VRM roller sleeves with proven heat treatment technology for my plant?

I select anti-cracking sleeves by choosing a supplier that can show a heat treatment system, not only a material grade. I focus on toughness balance, residual stress control, and proven repeatability in similar mills.

When my plant team asks me what to buy, I do not start from a brochure. I start from failure mode. If cracks and spalling are the top failure, then anti-cracking design and heat treatment proof come first. I also look for gradient designs when the application is severe, since a tough core plus a hard surface can reduce through-thickness cracking.

My buying rules are simple:

- I require a hardness profile, not a single hardness value.

- I require microstructure evidence, especially uniformity and interface quality for composites.

- I require batch traceability and furnace records.

- I ask for references in similar raw materials and similar mill size.

- I prefer vacuum or controlled-atmosphere capability when surface integrity matters.

- I ask how they stabilize retained austenite if dimensional stability is a known risk.

- I judge their answers by clarity. Clear answers usually mean controlled process.

This is also where Dafang-Casting fits my logic. I want sleeves that do not only resist wear, but also resist cracking under real mill shocks. I care about optimized quenching and tempering, grain refinement, stress relief after machining, uniform microstructure control, and stable repeatability, because those are the levers that protect my mill from unexpected crack failures.

Conclusion

Heat treatment improves anti-cracking performance because it reduces residual stress, refines grains, balances hardness with toughness, and keeps the microstructure uniform. It also protects bonding zones in metal-ceramic composites and helps prevent spalling. When I choose sleeves, I look for proof of repeatable heat treatment control, not only a hardness number. At Dafang-Casting, we use metal-ceramic composite technology with controlled heat treatment to help plants run longer with fewer cracks and fewer shutdowns.