I have seen plants buy a “good” roller sleeve and still lose weeks to cracks, vibration, and fast wear. The real problem is not price. The problem is mismatch. Each material pushes the roller in a different way, and the wrong match turns normal load into failure load.

Select roller sleeve material by matching the material’s abrasiveness, impact level, moisture, and fineness target to the sleeve’s crack resistance and wear mechanism. Clinker and slag need higher crack resistance under high pressure. Limestone needs cost-controlled abrasion resistance. Coal needs anti-impact design plus ignition-safe operation.

I used to think “harder is safer.” Then I watched a hard, brittle sleeve crack early on a mill that looked stable on paper. After that, I started to treat roller selection like process design. If I keep reading the material behavior, the sleeve choice becomes much clearer, and my downtime drops.

Why does my clinker grinding require higher crack-resistant roller materials?

Clinker grinding looks simple, but the load is brutal when you run high pressure and chase stable fineness. I have seen micro-cracks start at the surface and grow fast when the sleeve is too brittle. Once the crack grows, vibration rises, and then the bearing and reducer start to suffer.

Clinker needs roller sleeves that resist crack growth under high compressive stress and repeated impact from hard nodules. In practice, I pick materials with strong toughness and crack control, not only high hardness.

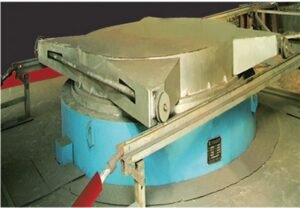

When I evaluate clinker, I start from what drives stress. Clinker is hard, abrasive, and often comes with a wide feed size range. Big nodules behave like hammers inside a stable grinding bed. If my mill runs a high differential pressure, the roller sees heavy cyclic loading. This is why high-chromium cast iron sleeves often show cracks even when wear looks acceptable. For clinker, I focus on crack resistance first, then wear resistance. I also check moisture and temperature because both change bed stability. A stable bed lowers impact, and that alone can extend life. I use a simple checklist and score each factor:

| Clinker factor I check | What it does to the sleeve | What I prefer in sleeve material |

|---|---|---|

| High hardness and abrasiveness | fast surface wear | high wear resistance + stable hard phase |

| Large feed nodules | impact and edge loading | high toughness, crack blocking structure |

| High fineness target | higher pressure and longer grinding | crack resistance under cyclic stress |

| Unstable bed / vibration | impact spikes | anti-crack design, strong bonding, stable operation |

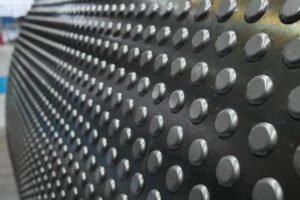

In my experience, metal ceramic composite sleeves help here because the ceramic phase provides wear resistance, while the metal matrix holds it and blocks crack growth when the load changes.

How do slag grinding conditions affect my choice of roller sleeve material?

Slag can look “softer” than clinker at times, but it can punish sleeves in other ways. I have seen slag setups where moisture and stickiness caused bed instability, then the mill hunted, and the roller took repeated shocks. Slag also pushes plants toward higher fineness, which increases pressure and time under load.

Slag grinding needs sleeves that handle abrasive wear plus moisture-driven instability, so crack resistance and anti-spalling behavior matter as much as hardness. I also treat drying and feed consistency as part of the sleeve choice.

When I select for slag, I always ask about moisture, mill type, and drying method. Many slag lines run with integrated hot gas drying, and moisture swings can change the grinding bed in minutes. A collapsing bed causes metal-to-metal contact or sudden high load zones, and that is where brittle sleeves fail. Slag’s grindability can be good, but the fine target often leads to more recirculation and more time under pressure. I also consider slag’s latent hydraulic properties. If overgrinding becomes common, energy goes up, and heat rises, and then the material flow changes again. In practice, I aim for sleeves that support stable wear and stable operation:

| Slag condition | Risk to rollers | Material feature I look for |

|---|---|---|

| Higher moisture | bed collapse and impact spikes | crack resistance + strong matrix bonding |

| Very fine product | longer load time, higher pressure | anti-fatigue cracking performance |

| Abrasive particles | steady wear | hard phase wear resistance |

| Wide feed variation | uneven stress | composite structure that spreads stress |

This is one reason I often recommend metal ceramic composite for slag. It gives me wear resistance without forcing me into a brittle structure that cracks during instability.

What roller material should I use for limestone to balance wear and cost?

Limestone usually does not need the same crack resistance level as clinker, and I do not want to overpay for a solution that my process does not require. I have seen plants buy top-end sleeves for limestone and then discover the bottleneck was separator tuning or feed size control, not sleeve life.

For limestone, I choose a material that matches moderate abrasiveness with controlled cost, often a tough wear-resistant alloy or a composite only when abrasiveness is high. The right answer depends on silica content, throughput, and downtime cost.

My limestone decision starts with chemistry and contamination risk. Limestone is easier to grind than clinker and slag, but some limestone has high silica or hard impurities that raise wear fast. I also consider the target fineness. If I run coarse product, I can use a simpler sleeve material and still get good life. If I run very fine, wear rises and energy rises, and then I may justify a higher grade. In many plants, the best savings come from lifecycle cost, not the cheapest sleeve. If a cheap sleeve forces frequent stoppages, my real cost is shutdown time, labor, and lost output. I use a practical view:

| Limestone case | What I usually do | Why it works |

|---|---|---|

| Low silica, stable feed | cost-focused wear alloy | wear is predictable and cracks are rare |

| High silica or sand contamination | higher wear solution, sometimes composite | abrasion dominates and costs rise fast |

| High throughput, high uptime need | longer-life option | shutdown cost is bigger than sleeve cost |

| Tight contamination limits | stable material chemistry | reduces risk of product quality issues |

So my limestone answer is rarely “the hardest.” It is “hard enough, tough enough, and easy to support locally.”

How can I choose anti-impact roller materials for coal grinding applications?

Coal grinding looks different because safety and stability matter as much as wear. I have dealt with cases where coal feed variation caused impact, then the roller edge wore fast, and then vibration rose. I also never ignore thermal sensitivity, because heat and sparks are not just maintenance problems.

For coal, I choose roller materials and designs that resist impact and edge chipping while supporting safe low-spark operation and inertization practices. I also pay close attention to moisture and drying because they change grinding behavior.

Coal often comes with variable moisture, variable hardness, and foreign objects. A sudden hard lump or tramp metal can create a sharp impact. If the sleeve is brittle, it chips. If it chips, debris circulates, and then wear accelerates and the mill becomes unstable. Many coal systems also run with hot air for drying, and the system must control oxygen and temperature. So I do not pick material in isolation. I align sleeve toughness with the system’s safety design. I also consider the mill type. A vertical mill needs stable bed control, while a ball mill system has different wear zones. Here is how I frame it:

| Coal factor | What it causes | What I choose for sleeves |

|---|---|---|

| Impact and foreign objects | chipping, edge failure | tougher structure, impact resistance |

| Moisture swings | instability, higher vibration | materials that handle load variation |

| Drying with hot air | higher temperature exposure | stable metallurgy, safe operation design |

| Safety requirements | ignition risk | low oxygen control + stable running surfaces |

In short, coal pushes me toward toughness and controlled operation. The best sleeve cannot fix a risky process, but the wrong sleeve can make risk worse.

Why is metal ceramic composite better for my mixed-material grinding conditions?

Mixed-material grinding is where many plants lose money, because they try to run one sleeve solution across mills with very different loads. I have seen a plant use a brittle high-hardness sleeve that worked on limestone, then it cracked quickly when moved to clinker duty. I have also seen a tough sleeve survive clinker but wear too fast on slag.

Metal ceramic composite is often better for mixed conditions because it combines high wear resistance from ceramic phases with crack and impact resistance from a tough metal matrix. It gives me a wider safe operating window when feed and conditions change.

When I think about mixed conditions, I think about failure modes. Some materials fail by steady abrasion. Some fail by cracking and spalling. Mixed grinding creates both, sometimes in the same shift. Moisture changes the bed. Feed size changes impact. Fineness changes pressure and time under load. A single-phase material struggles because it must be very hard to resist wear, but very hard can mean brittle. A composite structure gives me two jobs done at once. In our metal-ceramic composite approach at Dafang-Casting, I focus on strong bonding between phases so the ceramic does not fall out and the metal does not crack easily. I also look at how the hard phase is distributed so stress does not concentrate.

| Mixed condition | What I need from the sleeve | Why composite helps |

|---|---|---|

| Abrasion from slag/clinker | hard wear surface | ceramic provides strong wear resistance |

| Impact from feed variation | toughness and crack control | metal matrix absorbs shock |

| Long high-pressure grinding | fatigue resistance | structure slows crack growth |

| Maintenance and uptime pressure | stable wear pattern | reduces sudden failure events |

This is why composite is often my default recommendation when one plant needs one solution across several mills.

How do different raw material hardness levels influence my roller sleeve selection?

Hardness and abrasiveness look similar, but they are not the same. I have seen “medium hardness” material with hard quartz contamination cause faster wear than expected. I have also seen high hardness clinker behave well when the bed was stable and feed size was controlled. So I use hardness as a starting point, not the final answer.

Higher hardness and abrasiveness push me toward higher wear resistance, while higher impact risk pushes me toward higher toughness and crack resistance. The right sleeve is the one that matches the dominant wear and failure mode in my mill.

In practice, I map materials into a simple decision space: abrasion vs impact. Clinker and slag often sit high on both, depending on feed. Limestone usually sits lower on impact, but can rise on abrasion if silica is high. Coal often sits lower on abrasion but can be high on impact because of foreign objects and feed variation. I also bring in Bond Work Index and grindability because they indicate how much energy I will apply, and higher energy means higher stress on surfaces. Then I link this to mill type. A VRM with high differential pressure and fine target creates different stress than a ball mill. This is my simple mapping:

| Material | Typical dominant risk | What that means for sleeves |

|---|---|---|

| Clinker | cracking + abrasion | crack resistance + high wear resistance |

| Slag | abrasion + instability cracking | wear resistance + anti-spalling behavior |

| Limestone | cost-driven abrasion | “good enough” wear resistance, cost control |

| Coal | impact + safety | toughness + stable operation support |

This framework keeps me from making the common mistake of selecting only by hardness number.

How can I avoid premature cracking when grinding clinker and slag?

When cracking happens early, I usually find more than one cause. The sleeve may be too brittle, but the process often adds stress through unstable bed, high vibration, or poor feed control. I have solved several cracking cases by changing both the sleeve and the operating window.

To avoid premature cracking, I reduce impact and stress spikes by stabilizing the grinding bed, controlling feed size and moisture, and using sleeves with strong crack resistance and bonding. I treat cracking as a system problem, not only a material problem.

For clinker and slag, I watch three things first: feed size distribution, moisture swings, and vibration trend. Large nodules or a sudden wet feed can collapse the bed and create direct contact zones. That can start a crack even on a good sleeve. I also check grinding pressure and the separator settings because high recirculation can keep material in the mill longer and raise cyclic stress. Then I look at material selection. If the sleeve is high-hardness but low-toughness, it may crack under normal load variation. A metal-ceramic composite can help because it can resist wear while still slowing crack growth. I also review maintenance practices, because poor installation and uneven tightening can create stress concentration.

| Crack driver | What I change in operation | What I change in sleeve choice |

|---|---|---|

| Large feed nodules | improve crushing and screening | tougher, crack-resistant structure |

| Moisture fluctuation | stabilize drying and hot gas | anti-spalling, strong bonding |

| High vibration trend | tune bed and pressure control | crack-blocking composite design |

| Over-fine target with high load | optimize separator and recirc | fatigue-resistant wear solution |

When I do both sides, cracks stop being “mystery failures” and become preventable.

What material solution can extend my roller sleeve life across multiple mills?

When a plant runs several mills, the biggest hidden cost is not the sleeve price. It is the time spent managing different spare parts, different wear behaviors, and different failure risks. I have seen plants simplify this and gain stability just from using a standardized long-life solution in the most demanding lines.

A high crack-resistant, wear-stable solution like metal ceramic composite sleeves often extends life across multiple mills because it tolerates wider operating ranges and mixed wear modes. It also reduces spare variety and maintenance frequency.

I approach this as a lifecycle and reliability problem. If I select separate low-cost sleeves for each material, I may reduce purchase cost, but I increase downtime events and spare complexity. If I select one robust solution, I may pay more per sleeve, but I often gain from fewer stoppages, fewer emergency weld repairs, and more stable mill operation. I also check local support. If a sleeve grade is hard to source or slow to deliver, it creates risk. Our goal at Dafang-Casting is to make a sleeve that holds up under clinker and slag conditions, and still runs smoothly on limestone and coal when needed. The metal-ceramic structure helps because it balances wear and crack resistance. I still tailor details like hard phase ratio, matrix grade, and sleeve geometry for each mill.

| Plant goal | What I standardize | What I still customize |

|---|---|---|

| Fewer shutdowns | robust sleeve technology | hard phase design by material |

| Lower spare inventory | shared sleeve family | size, profile, and fit-up |

| Stable product quality | stable wear pattern | fineness and recirculation target |

| Faster support | common specs | installation and monitoring plan |

This is how I extend sleeve life without turning the plant into a “custom parts museum.”

How can I reduce my total grinding cost by selecting the right roller material?

I have seen plants focus on sleeve unit price and miss the bigger cost. The big cost is downtime, lost output, extra power, and repeated maintenance. A better sleeve can reduce power spikes and stabilize the mill, and that can be worth more than the sleeve itself.

To reduce total grinding cost, I select a sleeve that minimizes lifecycle cost: wear rate, cracking risk, maintenance hours, energy use, and lost production. The lowest purchase price rarely gives the lowest total cost.

My cost model is simple and practical. I compare options over a full campaign, not per ton of sleeve metal. If a sleeve lasts longer but causes instability, it may raise energy use and separator load. If a sleeve wears fast but never cracks, it may still be cheaper if replacement is quick and planned. So I need plant-specific numbers: throughput, power cost, shutdown cost per hour, and maintenance labor. I also include risk cost, because an unplanned failure can damage other components. Then I pick the sleeve that reduces the sum. I have used this table with many teams:

| Cost component | What sleeve choice can change | What I watch in operation |

|---|---|---|

| Wear replacement cost | campaign length | wear profile and tonnage to limit |

| Unplanned shutdown cost | crack and spalling risk | vibration, temperature, pressure trend |

| Energy cost | grinding efficiency | kWh/t and recirculation |

| Maintenance labor | ease and frequency | planned vs emergency work |

| Quality and contamination | material chemistry | product chemistry, stability |

This is why I often recommend metal-ceramic composite in high-risk lines. It can cut both wear and cracking events, which usually dominate total cost.

How do I get a customized roller material recommendation for my mill conditions?

I never give a serious recommendation based only on “we grind clinker” or “we grind slag.” The best choice comes from real operating data. When I get the right inputs, I can narrow down the sleeve structure and grade quickly, and I can predict the failure mode before it happens.

A customized recommendation needs your material properties, mill type, operating parameters, fineness target, and failure history, so the sleeve grade matches your real wear and crack drivers. With this, I can propose a sleeve design and a lifecycle plan, not only a material name.

Here is what I normally collect on one page. I keep it simple because plant teams are busy, and I do not want a long survey that nobody completes. I need material data: hardness indicators, abrasiveness clues, moisture range, feed size distribution, and chemical composition that may affect grinding behavior and contamination risk. I need mill data: mill type (VRM, ball mill, roller press), roller size, pressure range, table speed, separator type, and airflow and drying setup if any. I need performance targets: throughput, fineness, and PSD. I also need history: where cracks start, when wear accelerates, and what repairs were done. With those, I can match a sleeve design to your real conditions and also propose changes that reduce stress.

| Data I ask for | Examples | Why it matters |

|---|---|---|

| Material | moisture, feed size, chemistry, grindability | predicts wear and bed stability |

| Mill setup | type, pressure, airflow, separator | defines stress and temperature |

| Targets | tph, Blaine or residue, PSD | sets load and recirculation |

| Failures | cracks, spalling, vibration trend | shows dominant failure mode |

| Practical limits | local spares, lead time, shutdown window | controls risk and maintainability |

If you share these details, I can give a clear recommendation and explain why it fits, and I can help you reduce downtime and total cost in the same plan.

Következtetés

I select roller materials by matching the real wear and crack drivers of clinker, slag, limestone, and coal, not by hardness alone. I treat moisture, feed size, fineness target, and mill stability as part of material selection. When I need one solution across mixed conditions, I often choose metal ceramic composite because it balances wear resistance and crack control. If you want a customized answer, Dafang-Casting can recommend a sleeve design based on your mill data and your failure history.