Spalling and surface cracks do not start as “big failures.” They start as tiny stress points that grow with every load cycle. I have seen plants chase the symptom by changing brands, welding repairs, or raising hardness. The cracks still come back. The real problem is usually a mix of material stress, thermal shock, and small surface defects that turn into crack starters.

To prevent spalling and surface cracks, I focus on stress control first: uniform hardness from proper heat treatment, controlled cooling, clean machining that removes micro-notches, and stable operating conditions that avoid impact and thermal shock.

I learned this the hard way in early shutdowns where the roller looked “fine” one week, then showed a spider-web of cracks the next. Once I started treating cracks as a system problem, not a single defect, the failure rate dropped and the service life went up.

Why do my current VRM roller sleeves develop cracks so quickly?

Many sleeves crack fast because the stress inside the sleeve is already high before the mill even starts. If the heat treatment leaves uneven hardness, or if the cooling rate is not controlled, residual stress stays locked in. Then the mill adds cyclic loading, impact events, and thermal swings. The sleeve does not “wear out.” It breaks down from repeated stress.

Fast cracking usually comes from residual stress plus operating shock: uneven hardness, rapid cooling, thermal shock at startup and shutdown, micro-notches from machining, and impact loading from unstable feed.

When I review failed sleeves, I look for a pattern: cracks starting at the surface and branching, or cracks starting near edges and corners. These often point to surface stress raisers, not just “bad material.” I use a simple checklist and tie it to the mill history. Then I can separate material causes from operation causes.

| Cosa controllo | What it tells me | What I change |

|---|---|---|

| Hardness map across sleeve | If hardness is uneven, stress is uneven | Improve heat treatment and tempering control |

| Crack origin location | Surface notch vs thermal crack vs impact crack | Fix machining, startup, feed stability |

| Spall shape and depth | Fatigue spall vs brittle fracture | Adjust hardness range and toughness balance |

| Temperature trend during start/stop | Thermal shock risk | Slow warm-up and controlled shutdown |

| Vibration and bed stability | Impact and overload events | Stabilize feed, dam ring, pressure settings |

I also use NDT early, not after failure. If I find microcracks early, I can adjust operation and stop crack growth before the sleeve loses chunks.

How does metal-ceramic composite technology help me avoid spalling issues?

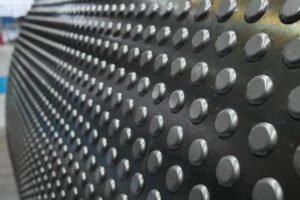

Spalling happens when the surface layer cannot carry repeated contact stress. Traditional high-chromium sleeves often rely on high hardness to fight wear, but that can raise brittleness. In a composite sleeve, I can keep strong wear resistance while also improving crack resistance. The key is how the ceramic phase is supported by the metal matrix, and how stress is spread instead of being concentrated at one brittle path.

Metal-ceramic composite sleeves reduce spalling by spreading contact stress through a tough metal matrix while hard ceramic particles take wear, so the surface resists fatigue without becoming brittle.

In real mills, spalling often follows small cracks that join into a spall boundary. A good composite structure interrupts that path. It does not mean “no cracks ever,” but it means cracks do not run fast, and chunks do not break off easily. I focus on three design points: the particle size and distribution, the matrix toughness, and the interface bonding. If any one is weak, spalling still happens.

| Composite design point | Perché è importante | What “good” looks like |

|---|---|---|

| Ceramic distribution | Avoids local stress peaks | Even, dense, no clusters |

| Metal matrix toughness | Blocca la crescita delle crepe | High crack resistance, stable under impact |

| Interface bonding | Prevents particle pull-out | Strong wetting, clean interface, no gaps |

| Residual stress control | Reduces hidden crack drivers | Controlled cooling and proper tempering |

This is why I do not judge composite sleeves only by hardness. I judge them by how stable they stay under shock, heat swings, and long fatigue cycles.

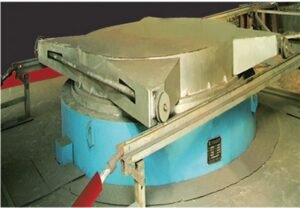

What factors in my cement or coal mill cause surface cracking on roller sleeves?

Surface cracking is often the mill telling you it is running with stress spikes. Cement and coal mills both create repeating load cycles, but the triggers can differ. In cement, hard inclusions, tramp metal, and unstable bed thickness can create impact. In coal, poor drying, uneven feed, and hot spots can raise thermal stress. In both cases, friction heat and thermal shock can turn a small surface defect into a crack starter.

Surface cracking is driven by cyclic loading plus stress spikes from impact, unstable bed, tramp metal, poor lubrication, and temperature swings during start, stop, and feed changes.

I connect mill conditions to crack types. If cracks are short and dense, I suspect thermal fatigue or surface stress. If cracks are long and directional, I suspect overload or repeated impact in one zone. I also pay attention to the “quiet problems” like micro-notches from finishing, because these start cracks even when operation looks normal.

| Mill factor | Typical symptom | Practical control |

|---|---|---|

| Tramp metal / hard lumps | Sudden vibration, chip spalls | Strong magnetic separation, stable feed screening |

| Unstable grinding bed | Impact marks, corner cracks | Stabilize feed rate and pressure, keep bed stable |

| Poor lubrication | Hot surface, fine cracking | Improve lubricant quality and delivery |

| Thermal shock | Network cracks after start/stop | Controlled warm-up and cool-down |

| Misalignment | One-sided wear and cracking | Check alignment and contact pattern |

When I see repeated cracking in the same area, I assume there is a repeating stress event. Then I find it, measure it, and remove it.

How can I improve the impact resistance of my grinding roller sleeves?

Impact resistance is not only a material choice. It is also how you control hardness and stress. If you push hardness too high, you may win wear resistance and lose toughness. I prefer uniform hardness in the recommended range, with proper tempering to reduce residual stress. Then I reduce impact events in the mill by improving bed stability and avoiding overload spikes.

To improve impact resistance, I balance hardness and toughness through proper heat treatment, control cooling to reduce residual stress, remove surface notches, and reduce impact events by stabilizing feed and grinding bed.

I use a simple rule from field experience: if a sleeve fails by cracking before it wears, it is not an “abrasion problem.” It is an “impact and stress problem.” In that case, raising hardness often makes it worse. Composite sleeves help because the metal matrix can absorb shock while the ceramic phase holds wear. But even with composites, poor heat treatment or poor interface bonding can still cause brittle behavior.

| Lever | Cosa faccio | Why it works |

|---|---|---|

| Heat treatment uniformity | Ensure even hardness and proper temper | Reduces stress peaks and brittle zones |

| Cooling rate control | Avoid fast uneven cooling | Prevents internal thermal stress |

| Surface finish | Remove micro-notches and sharp transitions | Stops crack initiation points |

| Operation stability | Avoid sudden feed changes and overload | Reduces shock loading cycles |

| Material selection | Use composite when impact is high | Keeps wear resistance with better toughness |

I also set up early inspections. If the first microcracks appear, I adjust operating load before the crack network grows.

How do I reduce thermal stress that leads to cracking in my mill rollers?

Thermal stress often comes from fast temperature changes and uneven heating. Startup and shutdown are the biggest risk points. If the mill heats the sleeve surface fast while the inside stays cooler, the surface expands and cracks. The same happens when water spray, wet feed, or sudden cold air hits a hot sleeve. I reduce thermal stress by smoothing temperature changes and lowering friction heat.

I reduce thermal stress by controlling startup and shutdown temperature ramps, preventing thermal shock, improving lubrication to cut friction heat, and keeping feed and drying stable to avoid hot and cold swings.

In practice, I track temperature and correlate it with crack growth periods. Many plants only look at production rate and vibration. Temperature is often ignored until failure. I treat it as a main signal. When I tighten thermal control, I often see crack density drop.

| Thermal stress source | What it looks like | What I change |

|---|---|---|

| Fast startup heating | Fine surface crack network | Slower warm-up, staged loading |

| Thermal shock from wet feed | Sudden cracks after feed upset | Stabilize feed moisture and drying |

| Friction heat | Hot spots, discoloration | Improve lubrication and contact conditions |

| Uneven airflow or hot gas | One-zone cracking | Balance airflow and heat distribution |

| Cold shutdown | Cracks after stops | Controlled cool-down, avoid sudden stop cycles |

This is also where proper heat treatment matters. If residual stress is high, thermal swings trigger cracks much faster.

Can upgrading to composite roller sleeves extend my service life and stop spalling?

Upgrading can extend life, but only if the composite design matches your real loads, heat swings, and impact level. I have seen upgrades fail when a plant picks a “harder” sleeve but ignores bonding quality, residual stress, and operating shock. When the composite is designed correctly, service life often improves because the wear phase and the toughness phase work together.

Composite sleeves can extend service life and reduce spalling when the design matches your mill’s impact and thermal conditions and the sleeve is heat-treated and cooled to control residual stress.

I evaluate upgrades like an engineering project, not a purchase. I compare failure modes, operating data, and inspection records. If the current sleeve fails by spalling and cracking before it wears, then a composite upgrade is often a good fit. If the current sleeve simply wears evenly to limit thickness, then I focus more on wear rate and cost per ton.

| Current failure mode | What it suggests | Upgrade direction |

|---|---|---|

| Early spalling | Surface fatigue and brittle zones | Composite with strong matrix support |

| Surface crack network | Thermal stress and residual stress | Composite + better thermal control |

| Corner and edge cracks | Impact and misalignment | Composite + alignment + stable bed |

| Even wear only | Pure abrasion dominant | Optimize wear layer, not only toughness |

If you want “stop spalling,” I set the goal as “reduce spalling risk to near zero under normal operation,” because abnormal events can still damage any sleeve.

How do I ensure strong bonding between ceramic particles and the metal matrix in my rollers?

Bonding is the heart of composite performance. If particles do not bond well, they pull out, leaving pits and crack starters. Good bonding needs clean interfaces, proper metallurgy, and controlled solidification. I also care about cooling rates, because large thermal gradients can weaken interfaces and raise residual stress around particles.

Strong bonding comes from clean interfaces, proper wetting during casting, controlled solidification and cooling, and heat treatment that avoids high residual stress at the ceramic-metal boundary.

In supplier reviews, I ask for microstructure evidence, process control records, and test results that relate to interface strength. I do not accept vague claims like “high bonding.” I want to see repeatable control. In my own checks, I look for particle clusters, interface gaps, and signs of pull-out on worn surfaces.

| Bonding risk | What I look for | What I request from supplier |

|---|---|---|

| Particle pull-out | Pits and rough voids on surface | Wear surface photos and failure analysis |

| Interface gaps | Cracks around particles | Microstructure images and QC standards |

| Clustered particles | Local brittle zones | Distribution control method |

| High residual stress | Early cracking without heavy wear | Cooling and tempering procedures |

| Poor wetting | Weak interface zones | Alloy design and casting parameters |

This is also why precise machining matters. If you leave micro-notches, the interface region becomes a crack highway under load.

What operating conditions should I optimize to minimize cracking in my VRM rollers?

Operation is where stress becomes real. Even the best material will crack if the mill runs with repeated impacts, overload peaks, and thermal shocks. I focus on keeping the grinding bed stable, avoiding sudden changes, and controlling temperature. I also keep lubrication stable, because friction heat adds stress right at the surface.

To minimize cracking, I stabilize the grinding bed, avoid overload and impact events, keep lubrication consistent, and control temperature ramps during start and stop to prevent thermal shock.

I treat this as a control problem. If vibration spikes happen at the same time each shift, it is usually a feed change or a control change. If cracks grow after unplanned stops, it is usually thermal shock. I use data trends, then set operating limits that the team can follow.

| Operating variable | Crack risk if unstable | Target behavior |

|---|---|---|

| Feed rate and size | Impact and overload | Smooth, controlled changes |

| Grinding pressure | Contact stress peaks | Stable within set range |

| Bed thickness | Metal-to-metal contact | Stable bed, avoid collapse |

| Temperature at start/stop | Thermal fatigue cracks | Controlled ramp up and down |

| Lubrication delivery | Friction heat and fatigue | Stable flow and clean oil/grease |

If you only optimize one thing, I pick startup and shutdown control, because that is where many crack networks begin.

How can I evaluate whether my current supplier’s roller sleeves are causing early spalling?

I do not judge a supplier by one failure, but I also do not ignore patterns. I compare expected life versus real life, then I look at the failure mode. Early spalling often points to brittle behavior, poor stress control, or weak surface integrity. I ask for hardness uniformity data, heat treatment records, and evidence of machining quality. I also request failure analysis support, not just replacement.

I evaluate supplier risk by comparing life and failure mode, checking hardness uniformity, heat treatment and cooling control, machining quality, and whether the supplier can provide microstructure and failure analysis for spalling cases.

In practice, I build a simple scorecard. If a supplier cannot show process control, the plant becomes the test lab. That is costly. I also compare sleeves from different batches. If performance varies widely, control is weak. I use NDT results to show how early cracks appear, then I push the supplier to respond with evidence.

| Supplier check | Perché è importante | What I ask for |

|---|---|---|

| Hardness range and uniformity | Uneven stress causes cracks | Hardness map and spec limits |

| Heat treatment procedure | Residual stress control | Full cycle and temper parameters |

| Cooling control | Prevent internal thermal stress | Cooling method and monitoring |

| Machining and finish | Micro-notches start cracks | Surface roughness and corner radius control |

| Failure analysis support | Improves next batch | Report with root cause and actions |

If they only offer “higher hardness,” I treat that as a warning sign when cracking is the main issue.

How do I get customized anti-cracking roller sleeves for my specific mill conditions?

Customization starts with real operating data and real failure evidence. I collect load conditions, vibration history, temperature trends, feed material characteristics, and photos of worn surfaces. Then I match material properties to those conditions. I also define the main failure mode, because anti-cracking design is different for thermal fatigue versus impact cracking. On the manufacturing side, I specify heat treatment targets, cooling control, and machining finish requirements, because these decide residual stress and crack initiation risk.

I get customized anti-cracking sleeves by linking your mill’s loads, impacts, and temperature swings to a material and heat treatment plan, then locking in cooling control, hardness targets, and machining finish standards.

When I work on a custom sleeve plan, I avoid guessing. I use the mill’s history. If the plant runs frequent stops, I focus on thermal stress resistance. If the plant sees tramp metal events, I focus on impact resistance and crack stopping. Composite sleeves give more room to design for both, but they still need controlled manufacturing. I also set inspection points so we can verify performance early, not after a major spall.

| Input I collect | Design decision it drives | Why it reduces cracking |

|---|---|---|

| Material grindability and lumps | Toughness and impact margin | Handles shock events |

| Start/stop frequency | Thermal fatigue resistance | Prevents crack networks |

| Temperature trend | Residual stress + thermal design | Lowers thermal stress peaks |

| Wear pattern | Contact distribution | Removes local overload zones |

| NDT crack maps | Crack origin control | Fixes real crack starters |

| Maintenance limits | Sleeve change plan | Avoids running into failure |

At Dafang-Casting, I build these sleeves around metal-ceramic composite technology and strict stress control: proper heat treatment for uniform hardness, controlled cooling to cut residual stress, and stable bonding that prevents particle pull-out. This is how I keep the sleeve strong in real mills, not just in lab claims.

Conclusione

Spalling and surface cracks come from stress, not bad luck. I prevent them by controlling residual stress with proper heat treatment and cooling, keeping hardness uniform, removing machining notches, and running the mill with fewer impact and thermal shocks. When the failure mode is cracking before wear, I often move to metal-ceramic composite sleeves. Dafang-Casting helps me match the sleeve design to my mill so I can extend service life and cut shutdown risk.