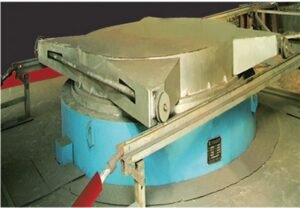

In my early mill days, I saw roller sleeves fail without warning. One loud bang, then cracks, vibration, and a rushed shutdown. The problem was not only wear. It was impact, and impact punishes weak toughness fast.

Impact resistance matters because it decides whether your VRM or coal mill roller sleeve can absorb shocks without cracking, spalling, or loosening. When impact resistance is low, small hits turn into microcracks, then big cracks, then downtime and high repair cost.

Impact is not a “maybe” load in grinding. It is a daily load that hides inside normal operation. When I start looking at impact as a system problem, I stop chasing cracks after they happen, and I start preventing them before they start.

Why does impact resistance matter for my VRM and coal mill roller sleeves?

I often meet engineers who focus on hardness first. I did the same years ago. Then I watched a very hard sleeve crack early, and I learned that hardness without toughness is a risky bet.

Impact resistance matters because it is your sleeve’s ability to take sudden energy and stay whole. In VRM and coal mills, the roller sees shocks from feed changes, tramp metal, and uneven bed thickness. If the sleeve cannot absorb that energy, the stress goes into cracks, not into safe elastic or plastic deformation.

What impact resistance protects in real mills

Impact does not only break sleeves. It also triggers a chain of problems. I have seen one small crack grow, then the roller starts to run rough, then vibration rises, then the bearing life drops, and then the whole mill schedule breaks. I also see bonding failures when the sleeve and core interface cannot take repeated shocks. That is why I treat impact resistance as “system stability,” not only “material strength.”

How it links to wear, fatigue, and bonding

Impact is a fatigue accelerator. One hard hit can start microcracks. Many small hits can grow them. If the sleeve is bonded to a core, bonding quality becomes a weak point. Poor adhesion acts like a crack starter. Temperature also changes the story. Low temperature raises brittleness. High temperature softens elastomers and lowers energy absorption.

| What you optimize | What improves | What can get worse if pushed too far |

|---|---|---|

| Higher hardness | Abrasion wear | Brittle cracking under shock |

| Higher toughness | Crack resistance | Faster wear if too soft |

| Better bonding | Interface life | Cost and process control need |

| Thicker section | Stress spread | Heat, alignment, fit issues |

When I pick a sleeve, I ask one simple question first: will it survive the shocks that my mill creates every day?

What causes impact loads and shocks in my grinding roller during operation?

I remember one coal mill where the operators blamed the sleeve supplier. The sleeve did crack. Still, the true root was the process. The mill was eating rocks and metal pieces like snacks.

Impact loads come from sudden changes in contact and force. In VRM, bed instability is a top source. When the grinding bed gets thin or breaks, the roller can hit hard surfaces. In coal mills, tramp metal, foreign stones, and uneven feed can create high shock events. Start-stop actions also add shocks, because thermal and mechanical conditions change fast.

Common shock sources I look for on site

I start with feed. Big lumps, moisture swings, and unstable dosing make impacts. Then I check the separator and circulation. High recirculation can create big chunks returning to the grinding zone. I also watch vibration trends. Short spikes often point to impacts. If the mill is misaligned, impacts become sharper because the load is not shared.

How shocks turn into damage

A single impact can create a small crack, but repeated impacts do the real work. They cause microcracking, then crack linking, then delamination or spalling. If there is a bonded sleeve, the interface can peel under cyclic shock. A rough or poorly designed surface can also create stress peaks at small contact points.

| Shock driver | What it looks like | What it damages first |

|---|---|---|

| Thin or collapsing bed | Sudden vibration spikes | Surface cracks, edge chipping |

| Tramp metal / stones | Loud bang, instant spike | Deep cracks, local spall |

| Feed moisture swings | Unstable bed, surging | Fatigue cracks over time |

| Misalignment | Constant uneven contact | One-side cracking, bonding stress |

When I reduce shock sources, I often extend sleeve life even before I change the material.

Why do my traditional high chromium roller sleeves crack under impact?

I have replaced many high chromium sleeves. They can be very wear resistant. Still, they often fail in the same way when impact is high. They crack, and the crack grows fast.

High chromium irons and similar hard alloys are strong in abrasion, but they are often limited in toughness. Their microstructure includes hard phases that resist wear, but these phases also make crack growth easier under shock. When impact energy arrives, a brittle structure cannot absorb it well. It releases it as crack initiation and propagation.

The “hard but brittle” trap

Hardness can hide risk. In a stable, low-shock mill, a hard sleeve may last long. In a high-shock mill, that same hardness can turn into early cracking. I have seen cracks start at stress concentrators like sharp corners, casting defects, pores, and local hard spots. Once a crack starts, cyclic impact acts like a hammer on the crack tip.

What makes cracking worse in practice

Real mills add more stress than lab tests. Thermal gradients can create extra stress. Poor fit or uneven contact raises local load. Repairs and weld overlays can create heat affected zones with different toughness. If the sleeve is thick but poorly cooled, residual stress can also help cracks start.

| Crack trigger | Perché è importante | Typical sign |

|---|---|---|

| Low toughness base material | Low energy absorption | Sudden crack after shock |

| Casting defects | Crack starter points | Cracks near pores or inclusions |

| Sharp geometry | Stress concentration | Cracks at edges and transitions |

| Residual stress | Adds hidden load | Cracks without clear shock event |

When I see repeated cracks in high chromium sleeves, I stop asking “who made it” and start asking “is this material right for my shocks.”

How does poor impact resistance increase my mill downtime and maintenance cost?

I once watched a plant lose a whole weekend because a sleeve cracked, then the roller started to vibrate, and then the team had to stop the mill to avoid bearing damage. The sleeve was the first failure, but the cost was much larger.

Poor impact resistance turns shocks into damage. Damage turns into unplanned stops. Stops turn into lost production, rushed labor, and risky repairs. It also increases secondary damage. Vibration can harm bearings, seals, housings, and even foundations. When the sleeve surface spalls, grinding efficiency drops, so the mill uses more power to do less work.

The hidden cost chain I track

I track cost in layers. First is the sleeve itself. Second is the shutdown time. Third is the collateral damage. Fourth is process loss, like unstable product fineness or reduced throughput. Poor impact resistance also forces more inspections. It pushes teams into reactive mode. That increases safety risk, because rushed work leads to mistakes.

Why fatigue matters as much as one big hit

Many failures are not from one huge shock. They are from repeated small shocks. That is fatigue. Microcracks grow slowly, then they reach a critical size, and then the sleeve cracks fast. If bonding quality is weak, cyclic impact can peel the interface even when the sleeve material is fine.

| Cost driver | Direct effect | Typical outcome |

|---|---|---|

| Unplanned shutdowns | Lost tons | Missed shipment windows |

| Emergency labor | Overtime | Higher injury risk |

| Secondary damage | Bearings, seals | Bigger repair scope |

| Process instability | Lower efficiency | Higher kWh/ton |

When I improve impact resistance, I am buying stable operation, not only longer wear life.

What materials offer the best balance between hardness and impact resistance for my roller sleeves?

In some industries, people use polyurethane and rubber sleeves for strong impact absorption. That is true, and I respect that. Still, in VRM and coal mill grinding zones, the wear, temperature, and load often demand metallic or engineered composite solutions.

The best balance depends on your wear mode, shock level, and temperature. Mid-range hardness often gives a good blend of energy absorption and wear resistance. In metal systems, that balance can come from tougher steels, engineered irons, or composite designs. In some low-wear, high-impact handling zones, elastomers can win. In grinding, I often look for a structure that is hard where it must resist abrasion, and tough where it must stop cracks.

How I compare material families

I separate materials by failure risk. Brittle high-hardness alloys resist wear but crack under shock. Tougher steels resist shock but may wear faster unless protected. Elastomers absorb impact very well, but heat and abrasive minerals can destroy them. Composite and gradient designs try to merge the best parts. They use a hard phase for wear and a tough phase for impact.

A practical selection view

I map my mill into zones: high abrasion, high shock, high temperature, and mixed. Then I match materials to zones. I also watch the bonding interface. Even the best material fails if the bond is weak. I ask for test data that matches real load spectra, not only a simple drop test.

| Material type | Resistenza agli urti | Wear resistance | Common limits in grinding |

|---|---|---|---|

| High chromium iron | Medio-basso | Alto | Brittle cracking under shock |

| Tough alloy steel | Alto | Medio | Faster wear without hard phase |

| Polyurethane / rubber | Very high | Low to medium | Heat, abrasion, chemical limits |

| Metal-ceramic composite | High (if designed well) | Alto | Needs strong process control |

I do not chase one “best” material. I chase the best balance for my exact shocks and wear.

How does metal ceramic composite technology improve impact resistance in my roller sleeves?

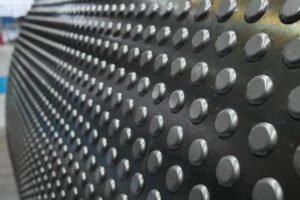

I used to think “ceramic” means brittle. Then I saw metal-ceramic composite sleeves that did not spall and did not drop studs. The key was not a ceramic block glued to metal. The key was a well-controlled composite structure.

Metal-ceramic composite technology improves impact resistance by combining a tough metal matrix with hard ceramic reinforcement. The metal matrix absorbs energy and stops cracks. The ceramic phase resists abrasion. If the interface is engineered well, the crack path gets blocked and deflected. That reduces crack growth under repeated impact loading. A gradient or layered design can push this further, because the surface can be harder while the inner zone stays tougher.

Why the structure matters more than the name

A composite is only as good as its bonding and distribution. If the ceramic is poorly bonded, it becomes a defect. If it is well integrated, it becomes a shield. I like designs that prevent ceramic falling, stud drop, and spalling, because those are impact-driven failure modes. I also look for stable operation signs, like low vibration and even wear patterns.

What I expect from a good composite sleeve

I expect a tough base that can take shocks without cracking. I expect a hard wear surface that can resist abrasion. I also expect the sleeve-to-core bonding to survive cyclic loads. Predictive impact testing that uses real load spectra is the most useful, because it matches how the mill actually hits the sleeve.

| Composite feature | What it does under impact | Cosa controllo |

|---|---|---|

| Tough metal matrix | Absorbs energy | Crack resistance data |

| Ceramic reinforcement | Reduces wear | Spalling resistance |

| Gradient/layer design | Spreads stress | Cross-section design |

| Strong interface bonding | Stops delamination | Bond test and QC records |

This is why I often choose metal-ceramic composite roller sleeves when the mill has both high wear and high shock.

How can better impact resistance help me achieve longer service life in my mill rollers?

I have seen two sleeves with similar hardness give very different life. The winner was not always the harder one. The winner was the one that stayed uncracked.

Better impact resistance extends service life by preventing the early damage that ends life first. In many mills, wear is not the first limit. Cracks, spalling, and bonding failure end the run before wear reaches the limit line. When impact resistance is higher, microcracks form later, and they grow slower. That keeps the surface stable, keeps vibration low, and keeps the load sharing even.

The service life model I use

I think of service life in stages. Stage one is “new and stable.” Stage two is “wearing but stable.” Stage three is “damage growth,” where cracks and spalls start. Impact resistance delays stage three. It also makes maintenance easier, because planned wear-based replacement is simpler than emergency crack-based replacement.

How it changes daily operation

When sleeves resist impact, operators feel it. The mill runs smoother. Alarms trigger less. The plant can hold throughput targets. Power per ton can improve because the grinding surface stays consistent. That also protects other parts, like liners, bearings, and hydraulic systems.

| What improves | Why it improves | What I monitor |

|---|---|---|

| Service life | Less crack-driven failure | Crack inspections, wear profile |

| Stability | Less vibration spikes | Vibration trend and peaks |

| Maintenance planning | Fewer emergencies | Planned shutdown schedule |

| Total cost | Less collateral damage | Parts spend and downtime hours |

If I want long life, I must stop cracks first, not only slow wear.

How do I evaluate whether a roller sleeve is suitable for my raw material and working conditions?

I once approved a sleeve based on a brochure. It looked perfect on paper. It failed early because my raw material had hard tramp inclusions and my mill had frequent bed collapse. That experience taught me to evaluate sleeves with my own conditions in mind.

I evaluate suitability by matching material behavior to my load, wear, and temperature. I look at toughness, fatigue resistance, and bonding quality, not only hardness. I also want evidence that the sleeve can handle repeated impacts, because many mills fail by microcracking and delamination. Testing must reflect real load spectra when possible, because simple static tests miss cyclic shock behavior.

The checklist I use before I buy

I start with the raw material. Is it abrasive, sticky, or lumpy? Then I check the mill. Does it have frequent vibration spikes? Does it run at low temperature or high temperature? Then I ask for material data: impact toughness, fatigue indicators, and wear data under similar media. For bonded sleeves, I ask how the bond is made and tested. Bonding quality is a common failure point under impact.

How I use structured comparison

I build a simple matrix and score options. I do not let one number like hardness decide. I also ask for reference cases in similar mills. If the supplier cannot explain failure modes and controls, I treat that as a warning.

| Evaluation factor | What to ask for | Perché è importante |

|---|---|---|

| Toughness / impact strength | Standard impact results + field evidence | Crack prevention |

| Resistenza alla fatica | Cyclic impact or load-spectrum approach | Microcrack control |

| Qualità dell'incollaggio | Bond method, QC, test records | Delamination risk |

| Temperature window | Hot/cold performance limits | Brittleness or softening |

| Geometry and fit | Tolerances and alignment plan | Stress concentration control |

A sleeve is “suitable” only when it matches my material, my shocks, and my temperature, all at the same time.

Can customized roller sleeve design improve impact resistance for my specific mill?

I have seen “standard” sleeves fail in non-standard mills. Some mills have uneven feed, some grind harder minerals, and some run with frequent starts and stops. In these cases, design is as important as material.

Customized design can improve impact resistance by reducing stress concentration and spreading load. Thicker cross-sections can distribute stress over a larger volume. Still, too much thickness can cause heat and alignment issues, so design must stay balanced. Surface profiling and controlled roughness can also reduce localized stress peaks. Layered or gradient designs can combine a tough inner zone with a wear-resistant outer zone.

Design levers that change impact behavior

I focus on three levers. First is geometry. Smooth transitions reduce stress concentration. Second is the section design. A stronger support behind the wear layer reduces bending stress. Third is the interface. The sleeve-to-core fit and bond design decide whether impacts peel the sleeve. I also consider how the design affects temperature, because extremes reduce impact resistance.

How I connect design to real failure modes

If I see edge cracks, I adjust edge geometry and contact pattern. If I see delamination, I focus on bonding design and core preparation. If I see local spall, I look at surface texture and reinforcement distribution. I also prefer suppliers who can model loads and test using real load spectra, because impact is not one clean event in a mill.

| Custom feature | Impact benefit | Risk if misused |

|---|---|---|

| Increased section support | Lower stress peaks | Heat and fit problems |

| Smooth transitions | Less crack start points | May change wear pattern |

| Gradient/layer materials | Toughness + wear balance | Process complexity |

| Surface profiling | More stable contact | Wrong profile can raise vibration |

When I customize design with real failure data, I often get a bigger gain than a material change alone.

How can I select a reliable supplier to ensure impact-resistant roller sleeves for my plant?

I have learned that “reliable supplier” means “reliable process,” not only a friendly sales call. Impact resistance depends on toughness, bonding, and quality control. If the supplier cannot control these, the best design still fails.

I select suppliers by checking their ability to deliver consistent toughness, strong bonding, and traceable testing. I want proof of impact and fatigue performance, not only hardness. I also want process transparency. For bonded and composite sleeves, bonding quality is a common failure point under impact, so I ask how they prepare the core, how they control the interface, and how they inspect it.

Questions I ask that reveal real capability

I ask for failure analysis examples, because good suppliers learn from failures. I ask for QC steps, because impact performance is sensitive to defects. I ask for reference projects in similar materials and mills. I also ask if they can support predictive impact testing using real load spectra. That is more reliable than a simple drop test for high-shock mills. I also check lead time and after-sales support, because quick response reduces downtime risk.

What a strong supplier relationship looks like

A strong supplier helps me match the sleeve to my raw material and working conditions. They recommend design changes when my shock pattern is high. They warn me when temperature limits will reduce impact resistance. They help me track wear and vibration, so the next sleeve is better, not just new.

| Supplier check | What good looks like | What worries me |

|---|---|---|

| Material control | Traceable heats, stable properties | “Same as last time” with no data |

| Bonding process | Clear method + test evidence | No bond tests, vague steps |

| Impact/fatigue testing | Realistic load approach | Only static or drop claims |

| Field support | On-site or remote diagnostics | No failure analysis ability |

| References | Similar mills and materials | Unrelated cases only |

At Dafang-Casting, I focus on metal-ceramic composite wear parts that keep stable operation under shock, so plants can extend life, cut downtime, and lower total cost.

Conclusione

Impact resistance is not a “nice to have” for VRM and coal mill roller sleeves. It controls cracking, spalling, delamination, and downtime. I look at toughness, fatigue, bonding, temperature, and design, not only hardness. I also match testing to real load spectra. If you want stable long-life rollers, I recommend working with Dafang-Casting (wenetting) and using our metal-ceramic composite solutions built for high-shock grinding.