In many plants I have visited, managers blame short wear life on the material grade. I used to think the same. Later, I saw good materials fail fast and normal materials last long. That gap always came from the foundry process.

Foundry technology decides real wear performance because it controls structure, stress, and defects, not just chemistry. Even the best alloy will fail early if casting, cooling, and heat treatment are wrong.

When I began to look past datasheets and into the casting shop, everything became clear. The foundry shapes how the material behaves under load, impact, and heat. This is where real performance is born.

Why does my wear part performance depend more on casting quality than material grade?

I often meet buyers who compare only chemical composition. That looks simple. But I have seen the same alloy perform very differently in two plants. The difference was casting quality, not grade.

Casting quality controls defects, grain size, and stress, which decide whether the material can survive real operating loads, even if the alloy grade is the same.

When metal solidifies, everything starts. If feeding is poor, shrinkage forms. If gas is trapped, pores remain. If cooling is uneven, stress builds inside. These problems do not show on a material certificate. They appear later as cracks, spalling, or sudden breakage.

In my early years, I replaced rollers that looked perfect on paper. After cutting failed parts, I saw loose structure, large carbides, and hidden voids. That experience taught me one lesson: performance is made in the mold.

| Factor | Good Casting | Poor Casting |

|---|---|---|

| Grain size | Fine and uniform | Coarse and mixed |

| Defects | Minimal | Shrinkage, pores |

| Stress | Low and balanced | High and uneven |

| Wear life | Stable | Unpredictable |

Casting quality turns alloy potential into real service life.

How does metal ceramic composite casting improve my wear resistance?

When I first worked with metal ceramic composites, I was skeptical. Later, after tracking rollers for years, I changed my mind. The casting method made the difference.

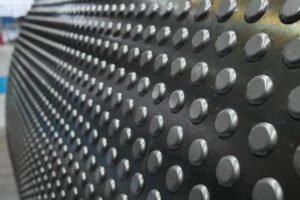

Composite casting locks hard ceramic phases inside a tough metal matrix, which resists wear while absorbing impact.

In composite casting, ceramic particles or studs are placed or formed during casting, not added later. The metal flows around them and bonds during solidification. This creates a mechanical and metallurgical lock.

If distribution is even, wear becomes slow and stable. If bonding is strong, ceramics do not fall out. I have seen mills where composite sleeves doubled service life because the wear surface stayed rough and effective.

| Aspect | Traditional Alloy | Metal Ceramic Composite |

|---|---|---|

| Wear mechanism | Matrix wear | Ceramic protection |

| Impact resistance | Medium | High with tough matrix |

| Wear rate | Increases over time | Stable |

| Failure mode | Cracks, spalling | Gradual wear |

Composite casting works only when the foundry controls placement, flow, and cooling.

Why do poor foundry processes cause cracking and early failure in my rollers?

Cracks rarely come from one cause. Most come from stress that was built during casting. I have seen cracks start before the roller even entered service.

Poor feeding, uneven cooling, and bad heat treatment create residual stress that later turns into cracks under load.

When thick and thin sections cool at different speeds, stress locks inside the part. If carbides are large and sharp, they become crack starters. During operation, cyclic load opens these weak points.

In one coal mill case, cracks appeared after only months. Metallography showed coarse carbides and high stress. The alloy was correct. The process was not.

| Root Cause | Effect |

|---|---|

| Fast local cooling | Hard brittle zones |

| Poor riser design | Shrinkage cracks |

| No stress relief | Crack growth |

| Bad carbide control | Brittle fracture |

Cracks tell the story of the foundry, not just the mill.

How does microstructure control affect the service life of my wear parts?

Microstructure is invisible during purchase. Yet it decides everything later. I learned this after cutting many failed parts.

Microstructure controls how wear, impact, and fatigue damage grow inside the material.

Fine, evenly distributed carbides resist abrasion. A tough matrix stops crack growth. If carbides cluster or grow too large, they break or pull out.

Foundries control microstructure through chemistry, cooling rate, and heat treatment. This is not random. It must be designed.

| Microstructure Feature | Result |

|---|---|

| Fine carbides | Slow abrasion |

| Uniform distribution | Even wear |

| Tough matrix | Impact resistance |

| Low segregation | Long fatigue life |

When microstructure is right, wear parts fail slowly, not suddenly.

How can advanced foundry technology reduce spalling and stud drop in my roller sleeves?

Spalling and stud drop are common complaints I hear. They often come from weak bonding, not bad operation.

Advanced foundry methods improve bonding between metal and ceramic, which stops surface failure.

In poor processes, ceramics sit in metal without real bonding. Under load, they loosen. Advanced casting uses controlled temperature, clean interfaces, and proper solidification paths.

I have tracked composite rollers that ran for years without losing a single stud. The key was casting control, not harder ceramics.

| Issue | Basic Process | Advanced Process |

|---|---|---|

| Bond strength | Mechanical only | Metallurgical |

| Stud retention | Unstable | Stable |

| Surface damage | Early spalling | Gradual wear |

Bonding is built during casting, not during operation.

Why does uniform ceramic distribution matter for my mill stability?

Uneven wear creates vibration. Vibration damages bearings and gears. I have seen mills suffer chain failures from this.

Uniform ceramic distribution ensures even wear and stable grinding forces.

If ceramics cluster, some zones wear slower. Other zones wear faster. The roller becomes uneven. Load shifts and vibration increases.

Foundries use layout design and simulation to control this. Random placement always causes problems later.

| Distribution | Mill Result |

|---|---|

| Uniform | Smooth operation |

| Clustered | Vibration |

| Missing zones | Local overload |

Uniformity protects not only the roller, but the whole mill.

How does heat treatment after casting impact my roller sleeve toughness?

I once saw two identical castings treated differently. One cracked. One survived years.

Heat treatment controls hardness, toughness, and stress balance after casting.

Quenching forms hardness. Tempering restores toughness. Stress relief removes internal tension. Skipping steps saves cost but shortens life.

| Heat Treatment | Effect |

|---|---|

| Proper quench | Wear resistance |

| Correct temper | Impact resistance |

| Stress relief | Crack prevention |

Heat treatment finishes what casting starts.

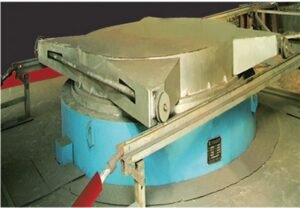

How can foundry process design be customized for my cement or coal mill conditions?

Every mill is different. I learned this by comparing clinker and coal mills.

Process design must match wear type, impact level, and temperature.

Coal mills need toughness. Cement mills need abrasion resistance. The foundry adjusts alloy, cooling, and composite design.

| Mill Type | Focus |

|---|---|

| Coal | Impact resistance |

| Cement | Abrasion control |

| Slag | High temperature stability |

Customization starts in the foundry, not in the warehouse.

How do I evaluate a wear part supplier’s foundry capability before purchasing?

I always advise buyers to look beyond brochures.

A strong supplier can explain process control, not just material grade.

Ask about simulation, microstructure checks, and heat treatment control. Ask for failure analysis experience.

| Question | Good Answer |

|---|---|

| Defect control | Clear methods |

| QC testing | Metallography, hardness |

| Process design | Explained clearly |

Capability shows in details.

How can I choose a foundry partner to maximize my wear part lifespan and reduce cost per ton?

After many projects, I learned that long life beats low price.

The right foundry partner reduces total cost by extending service life and stability.

A partner listens, adjusts, and improves. This saves shutdowns and repairs.

| Partner Type | Result |

|---|---|

| Price only | Short life |

| Process focused | Low cost per ton |

Kết luận

From my experience, real wear performance is built in the foundry. Alloy grade matters, but process control matters more. At Dafang-Casting, we focus on metal-ceramic composite technology, controlled casting, and deep service feedback. This approach helps plants run longer, safer, and at lower cost per ton.