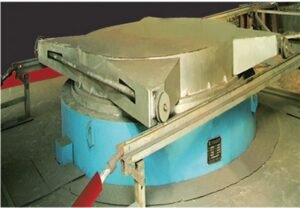

In many plants I have visited, roller sleeves fail earlier than expected. Cracks appear. Wear becomes uneven. Costs rise. The real problem often hides inside the material, not on the surface. When microstructure is ignored, wear resistance becomes guesswork.

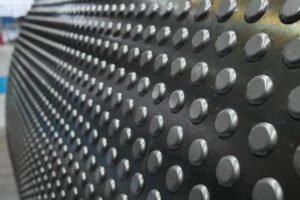

Microstructure analysis shows how grains, phases, and ceramic particles work together inside the roller sleeve, which directly explains why a VRM roller wears fast or lasts longer under real grinding loads.

I learned early in my career that two sleeves with the same hardness can behave very differently in service. The difference was always in the microstructure. Once I understood that, I stopped choosing rollers by hardness alone and started looking deeper.

Why should I evaluate the metal-ceramic composite microstructure before choosing my roller sleeves?

In many cases, plants select roller sleeves based on price or basic material grade. This creates hidden risks. Problems then appear only after installation, when shutdowns are expensive.

Evaluating the metal-ceramic composite microstructure before purchase helps predict wear life, crack risk, and stability under load, instead of relying on surface properties alone.

When I review microstructures, I focus on grain size, carbide shape, ceramic distribution, and porosity. These details show how the sleeve will behave in real grinding conditions. A fine and uniform grain structure supports stable hardness. Even carbide spacing reduces abrasive wear. A clean matrix lowers fatigue damage.

| Microstructure feature | What it tells me | Risk if ignored |

|---|---|---|

| Grain size | Hardness consistency | Local soft wear |

| Ceramic distribution | Load sharing | Spalling or vibration |

| Porosity level | Fatigue resistance | Early cracking |

This analysis gives me confidence before the roller ever enters the mill.

How does the bonding strength between ceramic particles and metal affect my roller’s lifespan?

Many failures I have seen start at the interface between ceramic particles and the metal matrix. If bonding is weak, particles detach. Wear accelerates.

Strong bonding between ceramic particles and metal allows load transfer and prevents particle pull-out, which directly extends roller sleeve service life.

In metal-ceramic composites, ceramics provide hardness, but metal absorbs impact. The interface must be clean and metallurgically bonded. Poor wetting or contamination creates weak zones. Under rolling load, cracks start here.

| Bonding condition | Result in operation |

|---|---|

| Strong metallurgical bond | Stable wear, low vibration |

| Partial bonding | Local chipping |

| Weak bonding | Rapid surface failure |

When bonding is correct, ceramics stay embedded and protect the surface instead of becoming debris.

What microstructural defects could be reducing the wear resistance of my current VRM rollers?

Some defects are invisible during normal inspection. I often see plants reuse rollers without knowing why wear accelerated.

Microstructural defects such as porosity, inclusions, and carbide clustering reduce wear resistance by creating weak zones that fail under rolling contact.

Porosity acts like a crack starter. Non-metallic inclusions interrupt load paths. Elongated carbides guide crack growth. These defects turn normal abrasion into fast failure.

| Defect type | Effect |

|---|---|

| Porosity | Fatigue cracks |

| Inclusions | Brittle fracture |

| Carbide clusters | Uneven wear |

Removing these defects through process control is often more important than increasing hardness.

How can I identify cracking risks in my roller sleeve through microstructure analysis?

Cracks never appear without warning. The warning signs exist inside the material long before failure.

Microstructure analysis identifies cracking risks by revealing stress concentrators, brittle phases, and poor phase balance in the roller sleeve.

I look closely at phase composition. Excess martensite increases hardness but lowers toughness. Retained austenite can absorb stress if controlled. Bainite offers balance.

| Phase | Crack behavior |

|---|---|

| Martensite | High hardness, brittle |

| Bainite | Balanced |

| Retained austenite | Stress absorption |

By adjusting heat treatment, cracking risk can be reduced before installation.

Why does a uniform ceramic particle distribution improve my mill’s grinding stability?

Uneven wear causes vibration. Vibration damages bearings and liners. Many plants blame operation, but the root cause is often material structure.

Uniform ceramic particle distribution ensures even load sharing, which stabilizes grinding pressure and reduces vibration in the mill.

When ceramic particles cluster, hard zones form. These zones wear slower than surrounding metal. The surface becomes uneven. Uniform distribution avoids this problem.

| Distribution | Grinding result |

|---|---|

| Uniform | Smooth operation |

| Clustered | Vibration |

| Sparse | Fast wear |

Stable grinding starts with stable microstructure.

How does microstructure impact the heat resistance of my roller during high-load operation?

High load creates heat. Heat changes microstructure. If the structure is unstable, wear accelerates.

Microstructure impacts heat resistance by controlling phase stability and carbide behavior during temperature rise under load.

Fine grains resist softening. Stable carbides keep hardness. Proper retained austenite transforms under stress and absorbs energy.

| Feature | Heat response |

|---|---|

| Fine grains | Stable hardness |

| Stable carbides | Low softening |

| Poor structure | Rapid wear |

Heat resistance is built during material design, not during operation.

What microstructure indicators show whether my roller sleeve will resist impact and vibration?

Impact resistance matters during start-up and material fluctuation. Vibration tests the material daily.

Microstructure indicators such as grain refinement, carbide shape, and phase balance show how well a roller sleeve resists impact and vibration.

Rounded carbides stop cracks. Clean matrices absorb energy. Controlled retained austenite transforms under stress.

| Indicator | Effect |

|---|---|

| Rounded carbides | Crack arrest |

| Clean matrix | Energy absorption |

| Balanced phases | Vibration control |

These indicators predict long-term stability.

How can advanced microscopy help me verify the quality of my roller sleeve?

Certificates do not show microstructure. Microscopy does.

Advanced microscopy allows direct verification of grain size, carbide morphology, bonding quality, and defects inside the roller sleeve.

SEM and optical microscopy reveal details hidden to the eye. I use them to confirm supplier claims.

| Tool | What I check |

|---|---|

| Optical microscope | Grain size |

| SEM | Bonding and carbides |

| Image analysis | Distribution |

This step removes uncertainty.

What microstructure features should I check to reduce my mill’s maintenance cost?

Maintenance cost grows when wear is unpredictable.

Checking microstructure features like homogeneity, porosity, and phase balance helps reduce unexpected shutdowns and repair cost.

Uniform structure means predictable wear. Low porosity limits crack starts. Balanced phases extend life.

| Feature | Cost impact |

|---|---|

| Homogeneity | Fewer repairs |

| Low porosity | Longer intervals |

| Stable phases | Planned shutdowns |

Predictability saves money.

How do I use microstructure analysis to select the right roller sleeve for my material conditions?

Different materials create different wear modes. One structure does not fit all.

Microstructure analysis allows roller sleeves to be matched to specific materials by predicting abrasion, impact, and heat behavior.

Coal needs impact resistance. Slag needs abrasion resistance. Clinker needs balance.

| Material | Microstructure focus |

|---|---|

| Kul | Tough matrix |

| Slag | Hard carbides |

| Clinker | Balanced phases |

This matching turns experience into data-driven selection.

Konklusion

Microstructure analysis explains why VRM roller sleeves fail or succeed. It links grain size, carbides, phases, and defects to real wear behavior. I have learned that stable operation starts inside the material. At Dafang-Casting, we use metal-ceramic composite microstructure design to deliver long life, low vibration, and predictable wear for demanding mills.