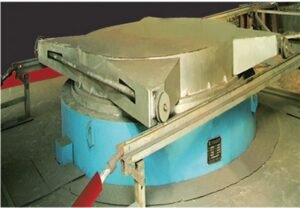

Every plant manager I meet has the same worry. Roller sleeves fail too early. Cracks appear. Wear turns uneven. Shutdowns come without warning. I have seen this problem many times in cement and coal mills. The real pain is not only the damage, but the lost production and pressure from management.

You can identify a high-quality composite roller sleeve by its internal structure, bonding strength, wear data, impact resistance, and proven performance in real mills. Good sleeves show uniform structure, strong metal-ceramic bonding, clear test data, and stable operation under real working conditions.

I learned early in my career that looking only at price or hardness numbers leads to mistakes. If you know what to check, you can avoid most failures before they happen.

What Material Structure Should I Look for in a High-Quality Composite Roller Sleeve?

Many roller sleeve problems start inside the material. I once cut open a failed sleeve after only six months of service. The surface looked fine. Inside, I saw voids and weak zones. The structure was the real cause.

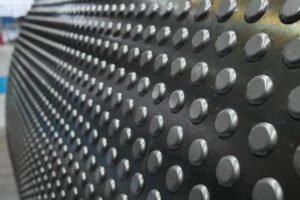

A high-quality composite roller sleeve has a dense and uniform metal-ceramic structure with no visible voids, cracks, or layer separation.

When I inspect a sleeve, I focus on how evenly the ceramic phase is distributed in the metal matrix. Good sleeves show consistent structure from the surface to the core. Poor sleeves often hide defects at the interface or edges. These defects grow under load and heat. Over time, they turn into cracks. A strong structure also depends on controlled casting or forming processes. Random distribution or manual mixing often creates weak points. In my experience, mills running clinker or slag need especially dense structures because abrasive particles attack every weakness. I also look at the machining quality. Precise outer diameter, roundness, and concentricity tell me the manufacturer controls the whole process, not just the material. When structure and geometry are both stable, the mill runs smoother. Vibration drops. Wear becomes predictable. That is the first sign of a sleeve I can trust.

How Can I Tell If the Metal Ceramic Composite Has Strong Bonding Strength?

Bonding strength is something many suppliers talk about but few can prove. I once watched a sleeve fail by layer peeling. The ceramic-rich layer separated from the base metal. The mill stopped in hours.

Strong bonding means the metal and ceramic phases act as one material, not stacked layers.

In good composite sleeves, the ceramic particles are metallurgically bonded to the metal matrix. There is no clear boundary line. I usually ask how the bonding is formed. Is it achieved during casting, infiltration, or sintering? Real bonding happens at high temperature with controlled chemistry. Visual inspection helps too. On cut samples, weak bonding shows sharp interfaces or micro cracks. Strong bonding looks gradual and continuous. I also check service records. Sleeves with poor bonding show early peeling, noise changes, and sudden vibration. Good bonding gives stable sound and smooth wear patterns. Over time, strong bonding prevents ceramic drop-out. That directly reduces damage to the mill table and other parts. For me, bonding strength is not a lab word. It shows up clearly after thousands of operating hours.

Why Do Some Composite Roller Sleeves Crack While Others Do Not?

Cracks are the biggest fear for maintenance teams. I have seen cracks appear even before full load. This usually means the material design ignored real stress conditions.

Composite roller sleeves crack when stress, impact, and thermal expansion are not balanced in the design.

In my experience, cracking often comes from excessive ceramic content or poor stress distribution. Ceramic is hard but brittle. If the metal matrix cannot absorb impact, cracks form at the ceramic edges. High-quality sleeves use a balanced ratio. The metal phase absorbs shock. The ceramic phase resists wear. I also look at residual stress from manufacturing. Poor heat control leaves internal stress locked inside the sleeve. Under load, this stress releases as cracks. Temperature changes matter too. Mills do not run at constant temperature. Good composites handle expansion without tearing apart. When I compare cracked and non-cracked sleeves, the difference is almost always in design discipline and process control, not in marketing claims.

How Does Ceramic Distribution Affect the Service Life of My Roller Sleeve?

Ceramic distribution decides how wear progresses over time. I once tracked two sleeves in the same mill. One wore evenly for years. The other showed pits and grooves after months.

Uniform ceramic distribution leads to steady wear and longer service life.

When ceramic particles cluster, they create hard islands. These islands take high load and crack the surrounding metal. The result is uneven wear and vibration. Good sleeves avoid clustering. The ceramic phase is spread evenly and aligned with the wear direction. This creates a self-protecting surface. As metal wears, ceramic gradually becomes exposed. This keeps the wear rate stable. I always ask suppliers how they control particle size and placement. Random distribution is risky. Controlled processes give predictable results. Over long campaigns, even distribution also protects the mill table and grinding track. That hidden benefit reduces total maintenance work.

What Performance Indicators Prove a Roller Sleeve Is Truly Wear-Resistant?

Many brochures list hardness values. Hardness alone misleads people. I learned this lesson early when a very hard sleeve failed fast.

True wear resistance is proven by wear rate, compressive strength, and stable performance over time.

I look for data that matches real conditions. Abrasion tests, impact wear tests, and long-term field data matter most. High-quality sleeves come with clear numbers for hardness, compressive strength, and expected wear rate under clinker or coal conditions. More importantly, these numbers stay stable after thermal cycling. If a supplier cannot explain how the data was measured, I stay cautious. Real wear resistance also shows in service. The surface becomes smooth, not broken. Power consumption stays stable. These signs tell me the sleeve is doing its job quietly, which is exactly what good wear parts should do.

How Can I Judge Impact Resistance for My Cement or Coal Mill Application?

Impact resistance is critical in coal mills and clinker grinding. I have seen sleeves shatter after foreign material enters the mill.

Impact resistance depends on matrix toughness, bonding strength, and internal stress control.

To judge impact resistance, I look beyond hardness. Toughness tests, drop tests, and fracture analysis matter. Good composite sleeves deform slightly under shock instead of cracking. This means the metal phase is doing its job. I also review past failure modes. If a sleeve survives tramp metal events with only surface marks, that is a strong sign. In my experience, sleeves designed only for abrasion often fail under impact. Balanced design always wins in real plants.

What Testing and Quality Control Should a Reliable Supplier Provide Me?

Quality control separates serious manufacturers from traders. I always ask for proof, not promises.

Reliable suppliers provide full testing data, batch traceability, and in-factory inspection records.

I expect hardness tests, chemical analysis, and dimensional inspection reports. For composite sleeves, bonding evaluation and microstructure inspection are important. Batch numbers matter too. If a problem appears, traceability allows correction. I also value factory visits or audit reports. When suppliers control every step, quality becomes consistent. This consistency reduces surprises during operation, which is what every plant needs.

How Do Working Conditions Influence My Choice of Composite Roller Sleeve Material?

No two mills are the same. I learned this after installing the same sleeve design in two plants with very different results.

Working conditions decide the correct composite design, not marketing claims.

Material hardness, feed size, moisture, and temperature all matter. Coal mills need impact and thermal stability. Slag grinding needs extreme abrasion resistance. High-quality suppliers adjust ceramic content, matrix composition, and geometry for each case. I always share operating data before choosing a sleeve. When design matches conditions, service life becomes predictable. When it does not, failure is only a matter of time.

Why Does a High-Quality Composite Roller Sleeve Reduce My Maintenance Cost?

Maintenance cost is more than purchase price. I have seen cheap sleeves cost more in one year than good sleeves cost in three.

High-quality composite sleeves reduce maintenance by extending life and stabilizing operation.

Longer service life means fewer shutdowns. Stable wear means fewer adjustments. Strong bonding means less damage to other parts. Over time, these effects add up. I also value easier refurbishment. Well-designed sleeves allow predictable repair or replacement planning. This turns maintenance from emergency work into scheduled work. That change alone saves money and stress.

How Can I Verify Real Application Cases Before Purchasing Roller Sleeves?

Real cases are the final proof. I never buy critical wear parts without them.

You can verify quality by reviewing case histories in similar mills and conditions.

I ask for operating hours, material type, and wear results. Photos help. So do references from other plants. Good suppliers share both success stories and limits. I trust suppliers who speak honestly about where their sleeves work best. This transparency usually reflects strong engineering confidence.

Conclusie

After many years in mills, I know that high-quality composite roller sleeves are defined by structure, bonding, testing, and real performance. At Dafang-Casting, we design metal-ceramic composite sleeves to meet real working conditions, not lab ideals. Our goal is simple. Longer life. Fewer failures. Lower cost. If you want predictable and stable grinding, choosing proven composite technology is the right step.