ผู้ผลิตที่ได้รับการรับรองมาตรฐาน ISO สำหรับโรงงานปูนซีเมนต์และเหมืองแร่ ตั้งแต่ปี 1992 | ได้รับความไว้วางใจจาก Sinoma, Jidong Cement และลูกค้ากว่า 100 รายทั่วโลก

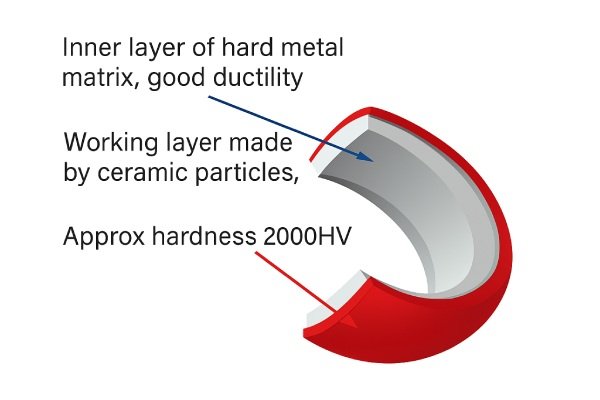

ปลอกลูกกลิ้งเหล็กหล่อโครเมียมสูงทั่วไปและลูกกลิ้งที่ซ่อมแซมผิวด้วยการเคลือบจะเสียความเหนียวต่อแรงกระแทกเพื่อแลกกับความแข็งที่สูงกว่า ส่งผลให้เกิดรอยร้าวและความล้มเหลวในการทำงาน ปลอกลูกกลิ้งแบบฝังบล็อกเซรามิกใช้เหล็กหล่อเหนียวเพื่อความต้านทานรอยร้าวที่เหนือกว่า โดยผสมผสานความแข็ง 200HB กับค่าการยืดตัว 7% เพื่อดูดซับความเสียหายจากแรงกระแทกได้อย่างมีประสิทธิภาพ

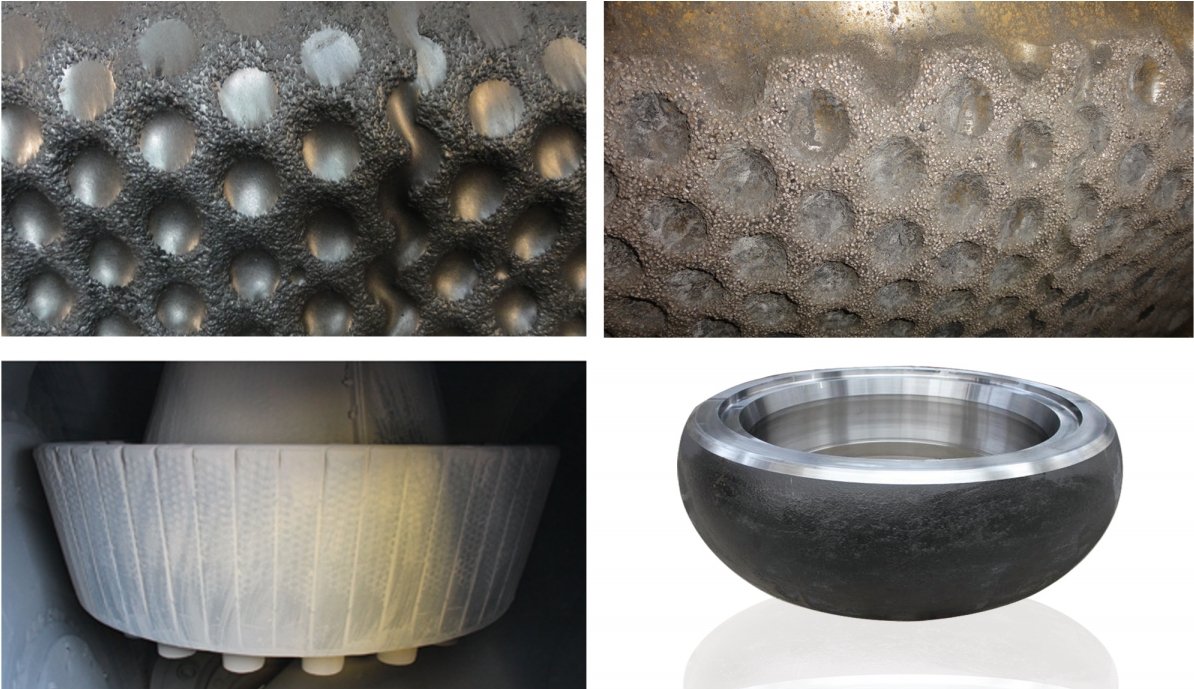

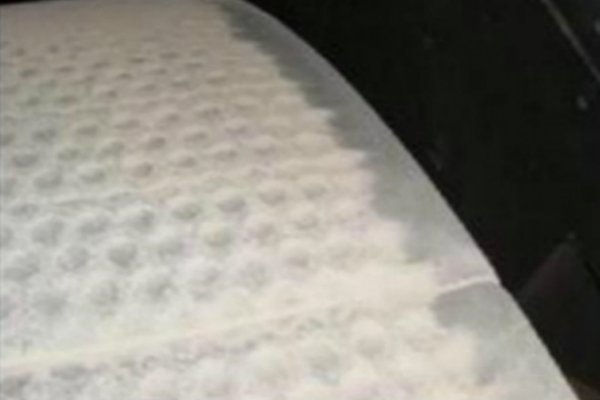

บล็อกเซรามิกทนการสึกหรอมีพื้นผิวการทำงานแบบรังผึ้ง ช่วยเพิ่มแรงกัดบนวัสดุที่บดและเพิ่มประสิทธิภาพการบด ลูกกลิ้งปลอกคอมโพสิตโลหะ-เซรามิกผสานอนุภาคเซรามิกกับโลหะผสมสูงเพื่อความทนทานและประสิทธิภาพที่เหนือกว่า

บล็อกเซรามิกทนการสึกหรอมีความแข็งที่ยอดเยี่ยม เกิน 60HRC และให้ความทนทานต่อการสึกหรอที่เหนือกว่าการเชื่อมทับหรือเหล็กหล่อโครเมียมสูง การสึกหรอที่สม่ำเสมอและการทำงานของเครื่องบดที่เสถียรทำให้มั่นใจในความน่าเชื่อถือในระยะยาว

ซินโนมา ผู้นำระดับโลกด้านวิศวกรรมโรงงานปูนซีเมนต์ ประสบปัญหาการสึกหรออย่างรุนแรงก่อนกำหนดในชิ้นส่วนสำคัญของเครื่องบดและเครื่องโม่ ซึ่งก่อให้เกิดการหยุดทำงานโดยไม่คาดคิดและค่าใช้จ่ายในการเปลี่ยนชิ้นส่วนที่สูง

ชิ้นงานหล่อมาตรฐานล้มเหลวทุก 4-6 เดือนภายใต้การสึกหรออย่างหนัก ทำให้ตารางการผลิตและงบประมาณการบำรุงรักษาถูกขัดจังหวะ

DaFang พัฒนาชิ้นส่วนหล่อโลหะผสมโครเมียมสูงด้วยการอบชุบด้วยความร้อนที่เหมาะสม ช่วยยืดอายุการใช้งานของชิ้นส่วนเป็น 12 เดือนขึ้นไป Sinoma ลดเวลาหยุดทำงานลง 40% และลดต้นทุนการเปลี่ยนชิ้นส่วนประจำปีลง 30% ทำให้การผลิตซีเมนต์ดำเนินไปอย่างราบรื่น

ปลอกเซรามิกคอมโพสิตผสานอนุภาคเซรามิกที่มีความแข็งสูง (เช่น อะลูมินาหรือเซอร์โคเนีย) เข้ากับเมทริกซ์โลหะที่มีความเหนียวสูง มอบคุณสมบัติ:

1、อายุการใช้งานยาวนานกว่าโลหะผสมมาตรฐาน 3–5 เท่า

2. มีความต้านทานการสึกหรอสูงสำหรับแร่ที่มีความแข็ง (เช่น แร่ที่มีซิลิกาสูง)

3. โปรไฟล์การบดที่เสถียรเพื่อให้ได้ความละเอียดและปริมาณการผลิตที่สม่ำเสมอ

ใช่ สามารถออกแบบตามความต้องการเพื่อให้เหมาะกับแบรนด์ VRM หลัก ๆ ได้ (เช่น Loesche, Polysius, Atox, OK Mill) ความเข้ากันได้ขึ้นอยู่กับ:

ข้อมูลจำเพาะด้านมิติ (เส้นผ่านศูนย์กลางภายนอก, เส้นผ่านศูนย์กลางภายใน, ความกว้าง)

การออกแบบการติดตั้ง (แบบยึดด้วยสลักเกลียว แบบแยกส่วน หรือแบบปลอกแข็ง)

ส่วนผสมของวัสดุ (ปรับให้เหมาะสมกับความแข็งของแร่/คลิงเกอร์เฉพาะ)

เวลาติดตั้งที่ใกล้เคียงกัน (ทั้งสองต้องถอดลูกกลิ้งออก) แต่ปลอกเซรามิก ลดความถี่ในการเปลี่ยน (เช่น 24–36 เดือน เทียบกับ 6–12 เดือน)

การออกแบบแบบแยกส่วนที่ติดตั้งล่วงหน้า สามารถลดเวลาหยุดทำงานได้มากยิ่งขึ้น

พิจารณา:

1、วัสดุที่ผ่านการประมวลผล (ความหยาบ, ความชื้น, ความแข็ง)

2、พารามิเตอร์การดำเนินงานของโรงงาน (ความดัน, อุณหภูมิ, รอบต่อนาที)

3. ปริมาณเซรามิก (เช่น อะลูมินา 30% สำหรับซีเมนต์ เทียบกับ 40% สำหรับแร่)

4. ความเชี่ยวชาญของผู้จัดจำหน่าย (ขอรายงานผลการตรวจทางห้องปฏิบัติการหรือข้อเสนอทดลองใช้)

ไม่, แม้ว่าจะมี 20–40% มีต้นทุนเริ่มต้นสูงกว่าพวกเขาให้บริการ ต้นทุนการครอบครองรวม (TCO) ที่ต่ำกว่า เนื่องจาก:

1、อายุการใช้งานที่ยาวนานขึ้น (มีการเปลี่ยนน้อยลง)

2. ลดแรงงานบำรุงรักษาและค่าใช้จ่ายในการหยุดทำงาน.

3、การประหยัดพลังงาน (สูงสุด 10%) จากประสิทธิภาพการเจียรที่คงที่

ใช่ วัสดุคอมโพสิตเซรามิก-โลหะขั้นสูงมีความสมดุล ความแข็ง (สำหรับทนต่อการสึกหรอ) และ ความทนทาน (สำหรับการต้านทานแรงกระแทก). พวกมันมีประสิทธิภาพเหนือกว่าปลอกมาตรฐานใน:

การบดปูนซีเมนต์คลิงเกอร์ (การขัดสีสูง + ความเครียดจากความร้อน)

การแปรรูปแร่เหล็ก/ทองแดง (มีปริมาณ SiO₂ สูง)

พวกเขาสามารถรักษาการกระจายขนาดอนุภาค (PSD) ให้คงที่ได้เนื่องจาก:

พื้นผิวที่ทนต่อการสึกหรอจะคงรูปทรงเดิมได้นานกว่า

แรงกดบดที่คงที่ช่วยหลีกเลี่ยงการลดลงของประสิทธิภาพเมื่อเวลาผ่านไป

การมีเครื่องจักรที่พร้อมใช้งานมากขึ้นช่วยเพิ่มกำลังการผลิตประจำปี

การบำรุงรักษาขั้นต่ำเทียบกับปลอกแบบดั้งเดิม การตรวจสอบสำคัญ:

ตรวจสอบการสั่นสะเทือนที่ผิดปกติ (บ่งชี้ถึงการติดตั้งที่ไม่ถูกต้อง)

ทำความสะอาดลูกกลิ้งเพื่อป้องกันการสะสมของวัสดุ

ตรวจสอบการบิ่นของขอบ (พบได้ยาก; เกิดจากเศษโลหะ)

วิศวกรที่เป็นมิตรของเราจะติดต่อกลับภายใน 8 ชั่วโมง