High-quartz raw materials are a hidden enemy in grinding systems. I have seen many plants focus only on capacity and output, while quartz slowly destroys their roller sleeves. Wear becomes faster. Cracks appear earlier than expected. Shutdowns turn from rare events into routine work. These problems drain maintenance budgets and reduce trust in the equipment.

Composite roller sleeves perform better for high-quartz raw materials because hard ceramic phases resist cutting wear, the composite structure spreads impact stress, and the surface remains stable under continuous quartz abrasion.

I learned this lesson after years of watching traditional sleeves fail again and again under quartz-rich feed. Once I understood how quartz attacks metal at the micro level, composite solutions became the logical answer. Let me explain this step by step, based on what I have seen in real mills.

Why Does High Quartz Content Cause Rapid Wear on My Traditional Roller Sleeves?

Quartz is not just another raw material component. It is one of the hardest minerals that enters a cement or power plant mill. When quartz content rises, wear behavior changes completely.

High quartz content causes rapid wear because quartz particles are harder than steel and act like sharp cutting tools that slice and plow the roller surface during grinding.

In my early years, I often heard operators say that wear was “normal.” But when I compared mills with low quartz and high quartz, the difference was dramatic. In high-quartz conditions, roller sleeves lost material much faster, even when operating parameters stayed the same.

Quartz particles have sharp edges. Under high pressure, these edges cut into metal. Once the surface is scratched, stress concentrates along the scratch. The scratch becomes a groove. The groove becomes a crack initiation site. This is how rapid wear turns into early failure.

| Quartz Property | Effect on Traditional Sleeve |

|---|---|

| High hardness | Severe cutting wear |

| Sharp geometry | Deep grooves |

| Uneven size | Local stress peaks |

| Continuous feed | Accelerated surface damage |

Traditional steel sleeves were never designed to fight this type of wear for long periods.

How Do Metal Ceramic Composite Roller Sleeves Resist Quartz Abrasion Better?

When I first examined a worn composite sleeve under quartz service, the wear pattern looked completely different. That difference explains everything.

Metal ceramic composite roller sleeves resist quartz abrasion because ceramic or carbide phases are harder than quartz and protect the metal matrix from direct cutting.

In a composite sleeve, ceramic particles form a hard skeleton on the surface. Quartz cannot easily cut these particles. Instead, quartz edges become dull or fracture. The metal matrix underneath supports the ceramic and absorbs impact energy.

This changes the dominant wear mechanism. Instead of deep grooves and tearing, wear becomes shallow and slow. Surface integrity remains intact for much longer.

| Composite Element | Function Against Quartz |

|---|---|

| Ceramic phase | Blocks cutting wear |

| Metal matrix | Absorbs impact |

| Composite interface | Shares load |

This combination is the key reason composites outperform monolithic metal sleeves in quartz-rich environments.

Why Do My High Chromium Rollers Fail Early Under High-Quartz Conditions?

High chromium rollers are often chosen for their hardness. But hardness alone does not guarantee long life under quartz attack.

High chromium rollers fail early because their brittle carbides crack and break under quartz cutting and repeated impact, exposing softer metal underneath.

In practice, I see the same failure sequence. Quartz scratches the surface. Chromium carbides fracture. Small pits appear. These pits grow into larger damaged zones. Cracks then propagate from these zones under cyclic load.

Thermal effects make it worse. Quartz grinding generates friction heat. High chromium steel does not tolerate thermal cycling well. Micro-cracks form due to thermal fatigue and then link together.

| Failure Factor | Result |

|---|---|

| Brittle carbides | Easy fracture |

| Quartz cutting | Surface damage |

| Thermal cycling | Crack growth |

This explains why high chromium rollers often fail far earlier than expected in high-quartz service.

How Can Composite Roller Sleeves Prevent Cracking and Spalling in My VRM?

Cracking and spalling are the most dangerous failure modes in a vertical roller mill. They often lead to sudden shutdowns.

Composite roller sleeves prevent cracking and spalling by distributing stress and stopping crack growth at material interfaces.

In a composite structure, stress does not concentrate in one continuous brittle phase. Ceramic particles interrupt crack paths. The metal matrix blunts crack tips and absorbs energy.

Bonding quality is critical. In well-designed composites, ceramic particles are tightly bonded to the matrix. They do not fall out under load. This prevents spalling, which is a common problem in poorly made hardfacing or studded designs.

| Protection Mechanism | Benefit |

|---|---|

| Stress dispersion | Lower crack risk |

| Crack interruption | Slower propagation |

| Strong bonding | No particle loss |

This is why composite sleeves offer safer and more stable VRM operation.

How Does Ceramic Particle Distribution Improve Wear Resistance With Quartz Materials?

Many people focus only on ceramic hardness. From my experience, distribution is just as important.

Proper ceramic particle distribution improves wear resistance by eliminating weak zones where quartz can initiate rapid wear.

If ceramic particles cluster together, other areas remain unprotected. Quartz quickly attacks these areas. Once wear starts, it spreads. I have seen composites fail early due to poor distribution, not poor material choice.

Uniform distribution creates a continuous barrier. Quartz encounters hard phases everywhere on the surface. Wear becomes even and predictable, which is ideal for maintenance planning.

| Distribution Pattern | Wear Behavior |

|---|---|

| Uniform | Slow, stable wear |

| Clustered | Local failure |

| Sparse | Fast material loss |

This is why manufacturing control matters as much as material selection.

Can Composite Roller Sleeves Extend My Service Life When Grinding Quartz-Rich Limestone?

This question comes up in almost every discussion with plant managers.

Composite roller sleeves can extend service life by two times or more when grinding quartz-rich limestone.

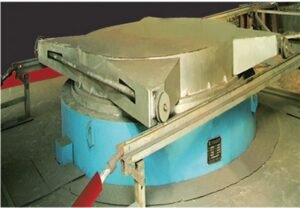

In real mills, longer life comes from stable surfaces. Composite sleeves maintain profile longer. Grinding pressure stays consistent. Product fineness stays stable. Operators do not need constant adjustments.

Uniform wear also prevents vibration. Reduced vibration protects bearings, gearboxes, and foundations. This indirect benefit is often overlooked but very important.

| Sleeve Type | Typical Life Under Quartz |

|---|---|

| High chromium | Short |

| Welded repair | Very short |

| Composite | Long and stable |

How Do Composite Rollers Reduce My Maintenance Cost Under High-Quartz Operation?

Maintenance cost is more than the price of a roller sleeve. It includes downtime, labor, and risk.

Composite rollers reduce maintenance cost by extending replacement intervals and preventing unexpected failures.

With longer service cycles, maintenance teams can plan shutdowns instead of reacting to emergencies. Spare parts inventory can be reduced. Safety risks also decrease because fewer emergency interventions are needed.

| Cost Element | Impact of Composite Sleeves |

|---|---|

| Spare parts | Lower consumption |

| Downtime | Shorter and planned |

| Labor | Less emergency work |

| Safety | Reduced risk |

These savings often exceed the initial cost difference between composite and traditional sleeves.

Are Composite Roller Sleeves Suitable for My Raw Mill and Coal Mill With Quartz Impurities?

Quartz is not limited to raw meal. Coal often brings hidden quartz contamination.

Composite roller sleeves are suitable for both raw mills and coal mills because they resist abrasion while absorbing impact loads.

Coal mills add impact and uneven feed conditions. Brittle materials struggle here. Composite sleeves combine hardness with toughness, which makes them reliable in both applications.

I have seen plants standardize composite sleeves across different mills to simplify maintenance and improve reliability.

| Mill Type | Composite Advantage |

|---|---|

| Raw mill | Abrasion control |

| Coal mill | Impact resistance |

How Can I Customize Roller Sleeves for My Specific Quartz Content and Mill Conditions?

No two mills operate under the same conditions. Customization is essential.

Composite roller sleeves can be customized by adjusting ceramic type, particle size, and matrix toughness based on quartz content and operating load.

Higher quartz levels need harder ceramic phases. Higher impact needs a tougher metal matrix. High temperature needs better thermal stability. A good design balances all these factors.

| Design Parameter | Custom Option |

|---|---|

| Quartz percentage | Ceramic hardness |

| Impact load | Matrix toughness |

| Temperature | Thermal resistance |

This tailored approach delivers consistent results instead of generic performance.

How Do I Select the Right Composite Roller Sleeve Supplier for High-Quartz Applications?

Even the best design fails without proper manufacturing and support.

The right supplier understands quartz wear mechanisms, controls composite bonding quality, and supports long-term operation.

I always recommend asking suppliers for real case data, not only lab tests. Field experience with quartz-rich materials matters. After-sales support also matters, especially during the first operating cycle.

| Selection Factor | Reason |

|---|---|

| Quartz experience | Correct material choice |

| Manufacturing control | Stable bonding |

| Technical support | Long-term reliability |

สรุป

High-quartz raw materials are one of the main reasons traditional roller sleeves fail early. I have seen this problem across cement, power, and mining plants. Metal-ceramic composite roller sleeves solve it by resisting abrasion, spreading stress, and maintaining surface stability. At Dafang-Casting, we design composite sleeves based on real mill conditions and real quartz challenges. If quartz is shortening your roller life, composite technology is the practical solution.