Cement grinding is a wear fight that never stops. I have seen plants spend good money on rollers, then lose it again through cracks, vibration, and early change-outs. The worst part is the uncertainty. You plan a shutdown for next month, then a sleeve starts spalling this week. That is the pain.

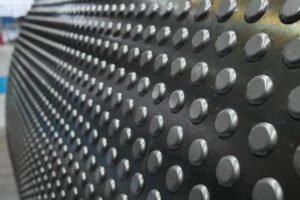

Metal-ceramic composite technology works by putting two jobs into one part: hard ceramic phases take the abrasion from clinker and additives, while a tough metal matrix carries the load and absorbs shock. This mix keeps the wear surface hard, but it keeps the body of the sleeve safe under impact and vibration.

In my work, the real value is not only “longer life.” It is also control. When the wear rate slows down and the wear shape stays even, the whole mill becomes easier to run. That is what I want for any plant that must keep stable output day after day.

Why should I choose metal-ceramic composite rollers instead of high chromium rollers?

High-chrome rollers often look strong on paper, yet they can fail in real mills. I have watched high-chrome sleeves wear fast in abrasive zones, then crack when the mill hits vibration or tramp metal. It turns into a cycle of repairs and unplanned stops, and the plant pays twice.

Metal-ceramic composite rollers are a better choice when your wear problem is not only abrasion, but also shock and cracking. The ceramic phase gives very high hardness against abrasive particles. The metal matrix gives toughness, so the sleeve can take impact loads without breaking like a brittle part.

In practice, I compare them by failure mode, not by hardness numbers alone. High-chrome relies on a hard structure in one material. That can work until the mill conditions change. A composite relies on two structures working together. The ceramic phase resists cutting and micro-ploughing from clinker, slag, and sand-like additives. The metal phase acts like a “shock buffer” and spreads stress instead of letting it build into a crack tip.

I also look at the wear profile. If the roller keeps a stable shape, the grinding gap and pressure stay more stable. That reduces vibration risk and helps keep product fineness steady. Below is how I explain it to plant teams:

| Item | High Chromium Roller | Metal-Ceramic Composite Roller |

|---|---|---|

| Abrasion resistance | Good, but depends on microstructure | Very high due to ceramic hardness |

| Crack risk under impact | Higher | Lower because matrix absorbs shock |

| Wear shape stability | Often uneven after long runs | More stable geometry |

| Maintenance approach | More repair and early change-outs | Longer intervals, fewer interventions |

| Best fit | Mild wear, stable feed | High abrasion + shock + vibration risk |

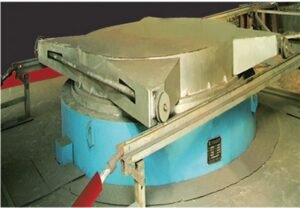

How does metal-ceramic composite technology improve wear resistance in my VRM?

In a VRM, the roller and table face do not see “smooth rubbing.” They see hard particles trapped under high pressure. Those particles cut the surface, then the wear grows faster once grooves form. I have seen this happen after only a short period when the feed changes or the reject rate climbs.

Metal-ceramic composite improves wear resistance by using ceramic phases that are much harder than the abrasive particles. The ceramic takes the contact and blocks cutting. At the same time, the metal matrix holds the ceramics in place and stops them from breaking out under load.

I think about VRM wear as two actions happening at once: abrasion and pressure fatigue. Abrasion is the direct cutting from hard particles. Pressure fatigue is the repeated compressive load that creates micro-cracks in weaker structures. A composite helps in both ways. The ceramic phase reduces the depth of scratches, so the surface stays flatter for longer. The matrix reduces stress concentration, so micro-cracks do not grow as fast.

When the wear stays low and even, the VRM keeps a better grinding geometry. That supports stable bed formation, stable vibration level, and stable power draw. It also helps the separator because fineness stays more consistent. I also pay attention to the ceramic volume fraction and the distribution. Too little ceramic and you lose wear resistance. Too much ceramic without good support and you risk brittle behavior. A good design keeps a balanced structure across the working layer, not only on the top surface.

| VRM problem | What causes it | How composite helps |

|---|---|---|

| Fast abrasion grooves | Hard particles + high pressure | Ceramics resist cutting |

| Local hot spots | Uneven contact and load | More stable contact surface |

| Rising vibration | Uneven wear and bed instability | Better wear profile stability |

| Short maintenance cycle | High wear rate | Lower wear rate, longer runs |

Why do my traditional roller sleeves crack while composite rollers do not?

When I inspect cracked sleeves, I usually see the same story: stress builds at a weak point, then a crack starts, then it grows with each load cycle. High-chrome materials can be strong, but they can also be less forgiving when the mill sees impact, vibration, or thermal swings. Small defects become crack starters.

Composite rollers resist cracking because the metallic matrix is built to be tough and to absorb shocks. The ceramic phase is hard, but it does not carry the whole structural load. The matrix carries and spreads the stress, so the crack driving force is lower.

In a cement VRM, cracks can come from several triggers: tramp metal, sudden feed changes, high vibration episodes, uneven pressure distribution, and repeated start-stop cycles. A high-chrome sleeve can form brittle zones or stress-raising carbides that do not like these events. Once a crack starts, it can travel fast if the material does not blunt the crack tip.

A metal-ceramic composite approach changes the crack path. The matrix can deform slightly and reduce peak stress. The ceramic phases act as wear blockers, but the matrix prevents a “straight-line” brittle fracture. I also see better behavior when the bond between ceramic and metal is strong, because then the structure works like one unit. Weak bonding can cause micro-voids, and those voids can act like crack starters. That is why bonding and process control matter as much as the recipe.

| Crack driver | Traditional sleeve outcome | Composite sleeve outcome |

|---|---|---|

| Impact shock | Crack initiates at brittle zones | Stress absorbed by matrix |

| Vibration cycles | Crack grows with fatigue | Lower fatigue crack growth |

| Local overload | Spalling and chipping | Better resistance to spalling |

| Thermal variation | Stress concentration | Better stress distribution |

How can metal-ceramic composite rollers extend the service life of my cement mill?

Service life is not only “how many hours until replacement.” It is also how stable the mill stays during those hours. I have seen sleeves that technically lasted long, yet the plant suffered because vibration rose, fineness drifted, and power went up. That is not real life extension.

Composite rollers extend service life by lowering the wear rate and keeping a stable wear profile. The ceramic phases reduce abrasive loss. The metal matrix keeps the structure intact under load. Together, they reduce early failure modes like spalling and cracking.

In most plants, the biggest hidden cost is the change-out cycle. Each time you change sleeves, you lose production, you risk alignment errors, and you spend labor hours. If a composite sleeve can run 2 to 2.5 times longer than a traditional option in the same duty, the whole planning style changes. You can schedule shutdowns instead of reacting to them.

There is also a process side. When the roller and table keep their designed geometry, the grinding gap remains closer to target. That helps bed stability and reduces the need for operators to “fight the mill.” Over time, stable geometry supports stable fineness and can reduce the risk of over-grinding or under-grinding. Another point I care about is contamination. Lower metal wear can reduce iron pickup in cement. That can help cement quality and downstream performance in some cases, especially when plants are sensitive to color, setting behavior, or performance consistency.

| Life driver | Effect on life | Composite impact |

|---|---|---|

| Abrasive wear rate | Determines material loss | Reduced by ceramics |

| Crack resistance | Avoids sudden failure | Improved by matrix toughness |

| Profile stability | Keeps grinding stable | Better over long runs |

| Maintenance frequency | Drives downtime | Lower change-out frequency |

How does strong ceramic-to-metal bonding benefit my mill operation?

If the bond is weak, the ceramic phase becomes a problem instead of a benefit. Ceramics can pull out, then the surface becomes rough, then wear speeds up. I have seen this in poorly made parts where the idea was good but the execution was not.

Strong ceramic-to-metal bonding makes the composite act like one material under load. It prevents ceramic pull-out and keeps the hard phase in the wear zone. That keeps the surface stable and reduces roughness-driven vibration.

In operation, bonding shows up as stability. With good bonding, the ceramics stay anchored even when the mill sees pressure peaks. The wear surface stays consistent, so the contact conditions do not jump around. That reduces sudden changes in vibration signals. It also reduces the chance of local “pits” forming where ceramics broke away. Those pits can act like stress raisers and can trigger spalling.

From a manufacturing view, bonding depends on process control. Casting or sintering routes must control temperature, wetting behavior, and interface design so the metal grips the ceramic and transfers load without forming weak layers. I also care about uniformity. If bonding quality varies across the sleeve, the wear will vary. That can lead to uneven pressure distribution and more vibration. Strong bonding, even distribution, and the right ceramic fraction together give the best operation results.

| Bonding issue | What you see in the mill | What good bonding changes |

|---|---|---|

| Ceramic pull-out | Pitting, rough surface | Smooth, stable wear face |

| Interface cracks | Early spalling | Lower spalling risk |

| Non-uniform bonding | Uneven wear | More even wear profile |

| Poor load transfer | Local overload | Better stress sharing |

Can metal-ceramic composite rollers reduce vibration and uneven wear in my VRM?

Vibration is one of the most expensive “silent killers” in VRM operation. I have seen plants accept high vibration as normal, then later find the roller face has uneven wear and the mill has been fighting itself for months. Uneven wear makes vibration worse, and vibration makes uneven wear worse.

Composite rollers can reduce vibration and uneven wear by keeping a more stable wear profile and resisting localized abrasion. When the surface stays closer to the designed shape, the grinding bed stays more stable and the load is more even across the roller.

In my checks, I connect vibration to three physical things: contact stability, bed stability, and profile stability. Contact stability means the roller and table surfaces meet evenly. Bed stability means the material layer is not collapsing or surging. Profile stability means the roller does not develop high spots and low spots that force the load to concentrate. Composite technology supports profile stability because the wear is slower and more uniform when ceramic phases carry abrasion.

That said, I do not treat composite as a magic fix. If the mill has poor alignment, unstable feed chemistry, or wrong pressure settings, vibration will still happen. What the composite does is reduce the part-driven causes of vibration. It also helps the mill recover faster from small disturbances because the surface is less damaged by short vibration events.

| Vibration source | Typical sign | Composite effect |

|---|---|---|

| Uneven roller wear | Rising vibration trend | Slows profile distortion |

| Local abrasion zones | Hot spots, noise | Hard phase resists wear |

| Surface roughness | Unstable signal spikes | Less pitting and pull-out |

| Load concentration | Edge wear | Better wear distribution |

How does this composite technology help me lower maintenance and shutdown costs?

Most maintenance cost is not the part price. It is the lost production and the chain reaction: emergency labor, rushed logistics, and process instability after restart. I have seen plants pay more for one unplanned stop than for a full set of sleeves.

Composite technology lowers maintenance and shutdown costs by extending change-out intervals and reducing sudden failures like cracks and spalling. Fewer interventions mean fewer shutdown windows, less labor, and fewer spare parts consumed per year.

I measure cost in “cost per ton,” not in “cost per sleeve.” A composite sleeve may cost more up front, but it can reduce the number of replacements. It can also reduce repair work because the sleeve stays structurally sound. Another cost lever is stability. If the mill runs with lower vibration and more stable fineness, operators spend less time adjusting, and the plant wastes less energy on unstable operation.

I also include safety. Every major sleeve change brings heavy lifting and hot work. Reducing change frequency reduces exposure. When plants plan fewer, more predictable shutdowns, they can align the work with other maintenance tasks and reduce total downtime days. This is where long-life wear parts give the strongest business value.

| Cost element | What drives it | Composite impact |

|---|---|---|

| Downtime hours | Early wear, cracks | Longer intervals |

| Labor and contractors | Emergency repairs | More planned work |

| Spare inventory | Frequent replacements | Lower annual usage |

| Startup loss | Instability after repair | Better stability over run |

| Risk and safety | Heavy change-outs | Fewer interventions |

Is metal-ceramic composite suitable for my raw mill, coal mill, or slag grinding?

Different mills have different wear types. Coal mills see erosion and some impact, and they need good safety control. Raw mills see mixed abrasion with changing feed. Slag grinding often brings higher abrasion and sometimes tougher conditions because slag can be hard and variable. I do not assume one design fits all.

Metal-ceramic composite is suitable for raw mills, coal mills, and slag grinding when abrasion is a major driver and the mill also sees shock or vibration risk. The design must match the material, the pressure, and the temperature range.

For raw mills, I focus on abrasive wear from limestone, shale, and sand-like components. A composite with a balanced ceramic fraction can protect the working surface and keep the profile stable. For coal mills, I look at impact and erosion from coal and quartz, plus the need for stable operation to avoid unsafe conditions. A tougher matrix with controlled ceramics can work well, but the design must consider ignition risks and operating temperatures. For slag grinding, I usually push for higher wear resistance because slag can be very abrasive and can punish weak materials.

The key is to match the composite structure to the duty. Ceramic type, size, distribution, and bonding all matter. So does the base metal selection. I also consider the mill type. VRM rollers, table segments, and liners each see different stress patterns.

| Application | Main wear type | Composite design focus |

|---|---|---|

| Raw mill | Abrasion + some impact | Balanced ceramic + tough matrix |

| Coal mill | Erosion + impact + vibration | Tough matrix, controlled ceramics |

| Slag grinding | High abrasion | Higher wear resistance, strong bonding |

How can I customize metal-ceramic composite roller sleeves for my specific working conditions?

Customization is where most plants win or lose. I have seen parts fail not because the technology was wrong, but because the design did not match the real feed, pressure, and operating pattern. A roller sleeve is not only a wear surface. It is also a stress part.

You customize composite sleeves by adjusting the ceramic volume fraction, ceramic type, distribution pattern, working layer thickness, and base metal matrix to match your abrasive level, impact risk, and operating pressure. The goal is to keep wear low without making the part brittle.

When I start a customization project, I collect operating facts, not opinions: feed chemistry and hardness, moisture, reject rate, pressure setting, vibration history, temperature profile, and past failure photos. Then I map the roller surface into zones. Some zones see more abrasion, some see more impact, and edges often see load concentration. A good composite sleeve can use zoned design, where higher ceramic content protects the worst abrasion areas while tougher matrix design supports impact-prone areas.

Manufacturing method also matters. Casting-based embedding can give strong integration when controlled well. Insert design, interface preparation, and process temperature control affect bonding. I also consider maintenance style. If a plant needs predictable long campaigns, I design for profile stability. If the plant has frequent feed changes, I design for toughness and crack resistance.

| Working condition | Custom lever | What I target |

|---|---|---|

| Very abrasive clinker/slag | Higher ceramic hardness/fraction | Lower wear rate |

| High impact events | Tougher matrix, graded structure | Crack resistance |

| Edge loading | Zone reinforcement | Even wear |

| High pressure grinding | Strong bonding + stable interface | Prevent spalling |

| Variable feed | Balanced design | Stable operation |

How do I evaluate the long-term cost efficiency of metal-ceramic composite rollers for my plant?

I do not judge cost efficiency by purchase price. I judge it by what the mill costs per ton over a full campaign. Many plants only compare one invoice to another, then later they pay the real bill in downtime.

To evaluate long-term cost efficiency, compare total cost per ton: sleeve cost + maintenance labor + lost production from downtime + energy impact from unstable grinding + spare inventory cost. Composite rollers often win because longer life and fewer failures reduce downtime and annual part consumption.

I build a simple model using plant data. First, I calculate the historical average life of high-chrome sleeves, including premature failures. Then I convert that into annual replacements and downtime hours. Next, I estimate what a longer-life composite campaign does to replacements per year. I also include the “soft costs” that show up in power and stability. If a stable wear profile reduces vibration events, the mill often runs smoother, and operators stop making heavy adjustments that waste energy.

I also check quality impact. Lower metal wear can reduce iron pickup, which can matter for some customers and product types. Finally, I test the decision with a sensitivity check: even if composite life is only, say, 1.7x instead of 2.5x, does it still win? In many real cases, downtime reduction alone makes it positive.

| Metric | High-chrome baseline | Composite target |

|---|---|---|

| Campaign life | Shorter | Longer |

| Unplanned stops | More likely | Less likely |

| Annual sleeve sets | Higher | Lower |

| Downtime cost | Higher | Lower |

| Cost per ton | Often higher in reality | Often lower over time |

สรุป

In cement grinding, metal-ceramic composite technology works because it combines hard ceramics for abrasion control with a tough metal matrix for shock and crack resistance. This structure helps me keep wear low, keep the profile stable, and cut vibration risk. Over time, it reduces shutdowns and lowers real cost per ton. At Dafang-Casting, I use this metal-ceramic composite approach to build long-life roller sleeves that help plants run longer and more stable.